In the world of industrial automation, communication between devices is paramount. If you’re grappling with communication issues with Omron PLCs over Ethernet, you’re not alone. This comprehensive guide delves into common pitfalls and provides practical solutions to ensure your Programmable Logic Controllers (PLCs) communicate efficiently. Whether you’re a seasoned engineer or new to Omron PLCs, understanding these concepts is crucial for optimizing your automation systems.

Why is Communication Vital in Omron PLCs?

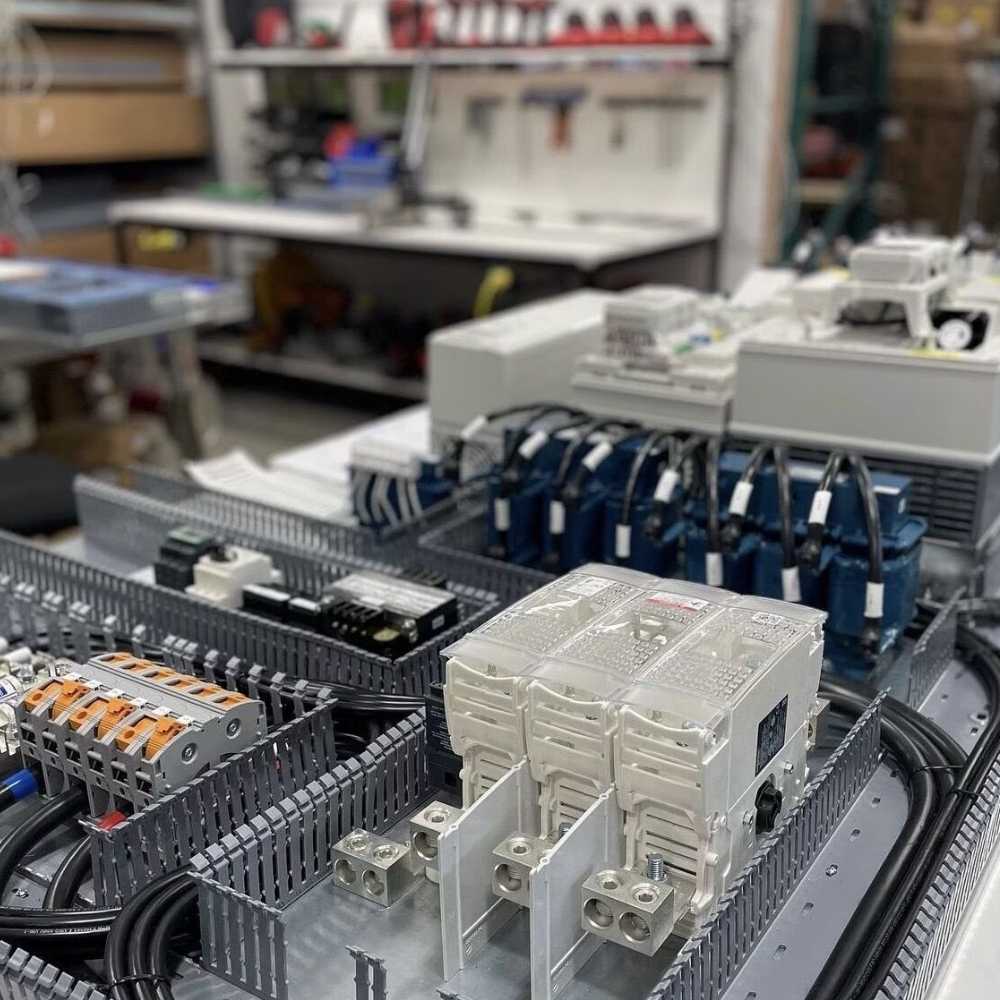

In industrial automation, Omron PLCs act as the brains of the operation, controlling machinery and processes. Effective communication allows these PLCs to communicate with other devices like HMIs, sensors, and other controllers.

- Inter-device Communication: PLCs must communicate with multiple devices to synchronize operations.

- Monitoring and Control: Real-time data exchange facilitates monitoring and adjustments, enhancing efficiency and reducing downtime.

- Integration: Seamless communication ensures that different components of the automation systems work together smoothly.

By ensuring reliable communication, you can optimize your processes and maintain operational excellence.

How to Troubleshoot PLC Communication Problems?

Experiencing PLC communication problems can halt production and lead to significant losses. Here’s how to identify and resolve these issues:

Inspect Physical Connections

- Check Ethernet Cables: Faulty or disconnected Ethernet cables can lead to communication failures. Inspect connectors and replace damaged cables.

- Verify Switches and Ports: Ensure that all network switches and ports are functioning correctly.

Review Configuration Settings

- IP Address Configuration: Incorrect IP addresses can prevent PLCs from communicating. Verify that each device has a unique IP address.

- PLC Program Settings: Ensure that the PLC program is correctly configured for communication protocols like FINS or EtherNet/IP.

Utilize Diagnostic Tools

- PLC Software: Use PLC software like Omron’s CX-One to analyze and diagnose issues.

- Network Monitoring: Monitor network traffic to detect any anomalies or interference.

Setting Up Ethernet Communication Protocols

Properly setting up Ethernet communication protocols is essential for reliable PLC operations.

Choose the Right Protocol

- FINS Protocol: Omron’s Factory Interface Network Service (FINS) is used for seamless communication between Omron devices.

- EtherNet/IP: An open protocol that allows communication with devices from other manufacturers, enhancing compatibility.

Configure PLC Settings

- IP Addressing: Assign unique IP addresses to each PLC and device. Avoid conflicts that can lead to communication issues.

- Port Settings: Ensure the correct port numbers are used for the chosen protocol.

Software Configuration

- Programming Software: Utilize Omron’s CX-Programmer to set up the communication parameters in your PLC programs.

- Firmware Updates: Keep your PLC’s firmware and software up to date for optimal compatibility and performance.

For more detailed guidance on Omron PLC programming, visit our Omron PLCs guide.

Common Communication Errors and How to Resolve Them

Even with proper setup, you might encounter communication errors. Here’s how to tackle them:

Error Messages and Codes

- Timeout Errors: Occur when a device doesn’t respond in time. Inspect network congestion and device load.

- Data Mismatch: Incorrect data registers can cause errors. Double-check your PLC programs.

Addressing Compatibility Issues

- Device Compatibility: Ensure all devices are compatible with your PLC’s communication protocols.

- Third-party Devices: When using devices like Mitsubishi or Allen-Bradley, verify communication protocol support.

Handling Environmental Factors

- Interference: Electromagnetic interference can disrupt communication. Use shielded cables and proper grounding.

- Network Layout: A poorly designed network can cause issues. Consider network segmentation and proper LAN setup.

For advanced troubleshooting, consider consulting with an Omron industrial automation specialist.

Best Practices for Reliable PLC Communication

Maintaining robust PLC communication requires adherence to best practices:

Regular Maintenance

- Update Firmware: Keep devices updated to address known issues.

- Monitor Networks: Regularly check for unusual network traffic or interference.

Proper Configuration

- Standardize Settings: Use consistent configuration settings across devices.

- Document Changes: Keep records of any changes to the PLC programs or network setup.

Training and Resources

- Staff Training: Ensure your team understands the communication protocols and troubleshoot techniques.

- Manufacturer Guidelines: Follow Omron’s manufacturer guidelines for optimal performance.

Enhance your system with compatible devices like Omron HMIs for improved monitoring and control.

FAQs

How do I assign an IP address to my Omron PLC?

Use the CX-Programmer software to access your PLC’s settings. Navigate to the network configuration and assign a unique IP address that matches your network’s scheme.

Can I use third-party devices with Omron PLCs?

Yes, Omron PLCs support standard communication protocols like Modbus and EtherNet/IP, allowing integration with devices from other manufacturers. Always verify compatibility before integration.

What causes communication timeouts in PLC networks?

Communication timeouts can be due to network congestion, incorrect port settings, or faulty hardware. Analyze your network traffic and check device configurations to resolve this issue.

How often should I update my PLC firmware and software?

Regular updates are recommended. Check for updates at least twice a year or whenever you encounter a communication issue that could be resolved with a firmware update.

Is wireless communication reliable for PLCs?

While wired connections are preferred for their stability, wireless solutions can be used with proper security and interference management. Assess your operational environment to determine suitability.

Where can I find reliable Omron PLC suppliers?

You can find authentic products and support at Omron PLC Supplier.

Conclusion

- Effective Communication: Essential for optimizing industrial automation with Omron PLCs.

- Troubleshooting Steps: Inspect, verify, and analyze to resolve issues.

- Proper Configuration: Accurate settings prevent most communication errors.

- Regular Maintenance: Updates and monitoring ensure reliable communication.

- Best Practices: Follow guidelines and train staff for optimal results.

For more resources on Omron products, explore our offerings on Omron Sensors and Omron Cables.