Programmable Logic Controllers (PLCs) are the backbone of modern industrial automation. When an Omron PLC system encounters problems, it can lead to costly downtime and disrupted manufacturing processes. This comprehensive guide will help you diagnose and resolve common issues in Omron PLC programming, ensuring your industrial operations run smoothly. Whether you’re an experienced engineer or new to PLCs, understanding these troubleshooting techniques is invaluable.

Why Is Regular Maintenance Crucial for Your Industrial Automation?

Regular maintenance is essential to ensure your PLC system operates efficiently and to prevent unexpected failures.

The Importance of Regular Maintenance Checks

Performing regular maintenance checks helps in early detection of potential issues that could lead to system failure. Key activities include:

- Inspecting hardware components for signs of wear or damage.

- Checking cable connections to ensure they’re secure.

- Verifying PLC settings and configurations for accuracy.

- Ensuring firmware and software are up-to-date.

By staying proactive with maintenance, you can avoid significant downtime and optimize your system’s performance.

Preventing Failure Through Maintenance

Neglecting maintenance can lead to:

- Hardware failures due to worn-out components.

- Data loss from unforeseen power outages.

- Disruption in production causing delays and increased costs.

Regular maintenance not only ensures reliability but also extends the lifespan of your programmable logic controllers.Explore Omron’s maintenance solutions for PLCs.

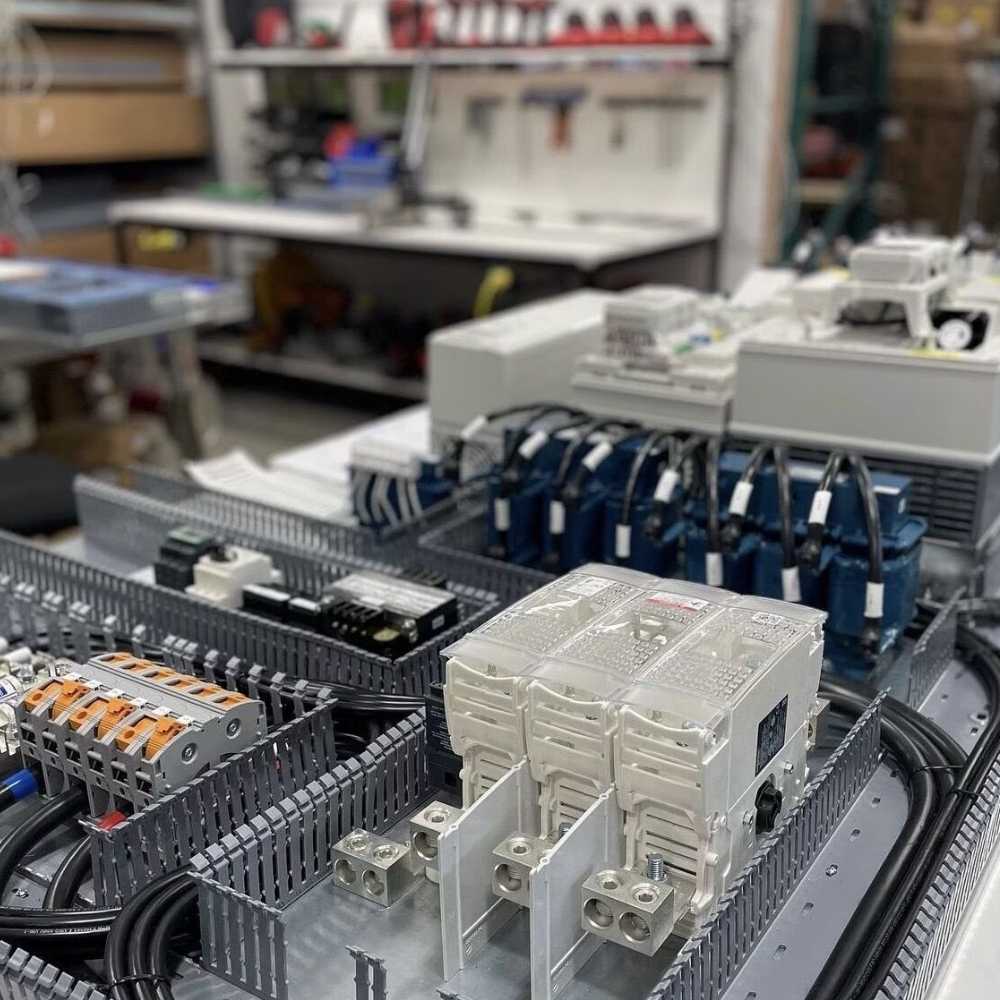

How to Diagnose Hardware Failures in Omron PLCs?

Identifying hardware issues promptly is key to resolving PLC problems.

Steps to Inspect and Diagnose Hardware Issues

- Check the Power Supply: Ensure the power supply voltage matches the PLC’s requirements. An incorrect voltage can lead to malfunction or damage.

- Inspect Modules and Components: Look for visible signs of damage on the CPU, I/O modules, and other components. Faulty hardware components are common causes of PLC failures.

- Verify Connections: Make sure all cable connections are secure. Loose or improperly connected cables can cause intermittent issues.

Utilizing Diagnostic Tools

- Use diagnostic LEDs on the PLC to identify error codes.

- Employ software tools like CX-One to analyze the PLC’s status.

- Inspect for signs of electromagnetic interference, which can affect PLC operations.

If hardware issues persist, it may be necessary to replace components with genuine parts from leading brands like Omron or Siemens.Find original Omron hardware components here.

What Are Common Configuration and Firmware Issues, and How Can You Resolve Them?

Incorrect configurations and outdated firmware can lead to PLC inefficiencies and failures.

Verifying PLC Configuration Settings

- Check all configuration parameters in your PLC programming software to ensure they match your system requirements.

- Ensure that the logic in your program does not contain errors that could cause unexpected behavior.

- Use tools like TIA Portal for managing configurations in Siemens PLCs.

Updating Firmware for Optimal Performance

- Backup your PLC programs and configurations before updating firmware to prevent data loss.

- Download the latest firmware from the manufacturer’s website.

- Implement firmware updates carefully, following the provided instructions to avoid incorrect installations.

Keeping your firmware updated ensures your PLC operates with the latest features and security patches for optimal performance.Learn how to update Omron PLC firmware safely.

How to Troubleshoot Wiring and Cable Connection Issues in PLC Systems?

Wiring problems can lead to intermittent failures and inefficiently operating PLCs.

Checking Wiring and Cable Connections

- Inspect all wiring for signs of wear, damage, or faulty connections.

- Use a multimeter to verify continuity and proper voltage levels.

- Ensure that RJ45 Ethernet cables are securely connected and free from damage.

Preventing Electromagnetic Interference

- Keep wiring organized and away from sources of electromagnetic interference.

- Use shielded cables where appropriate.

- Regularly check for signs of damage that could lead to interference.

Proper wiring practices help prevent disruption in your PLC system and maintain reliable operations.Get high-quality Omron cables for your PLC setup.

When Should You Seek Technical Support for Complex PLC Issues?

Some issues require expertise beyond regular troubleshooting methods.

Identifying Complex Issues

- Persistent problems after standard checks.

- Unexplained error codes or system behaviors.

- Suspected software bugs or corrupted programs.

Reaching Out for Expert Help

- Don’t hesitate to contact technical support when needed.

- Provide detailed information about the issue, including error messages and steps already taken.

- Engineers with specialized knowledge can provide insight and practical solutions.

Seeking assistance can save time and prevent prolonged downtime in your operations.Contact Omron’s technical support for expert assistance.

FAQs

How often should I perform maintenance on my Omron PLC?

Regular maintenance should be performed at least semi-annually, though more frequent checks can prevent issues in high-use environments.

What should I do if my PLC program is not running as expected?

Check the logic of your program for errors, verify configurations, and ensure all components are functioning properly.

How can electromagnetic interference affect my PLC, and how do I prevent it?

Electromagnetic interference can cause incorrect signals. Use shielded cables and proper grounding to resolve this issue.

Is it okay to mix components from different brands in my PLC system?

While possible, it’s best to use components from the same brand like Omron to ensure compatibility and reliability.

What are the signs of a faulty PLC module?

Indicators include unexpected system behavior, error codes, and LEDs showing fault statuses.

Can firmware updates improve my PLC’s performance?

Yes, updating firmware can fix bugs and improve efficiency. Always backup your system before updating.

Conclusion

- Perform Regular Maintenance to prevent failures and extend the life of your PLC.

- Diagnose Hardware Issues promptly to minimize downtime.

- Verify Configuration and Firmware settings regularly.

- Inspect Wiring to prevent interference and connection problems.

- Seek Technical Support for complex or unresolved issues.

- Use Genuine Components to ensure system compatibility and reliability.