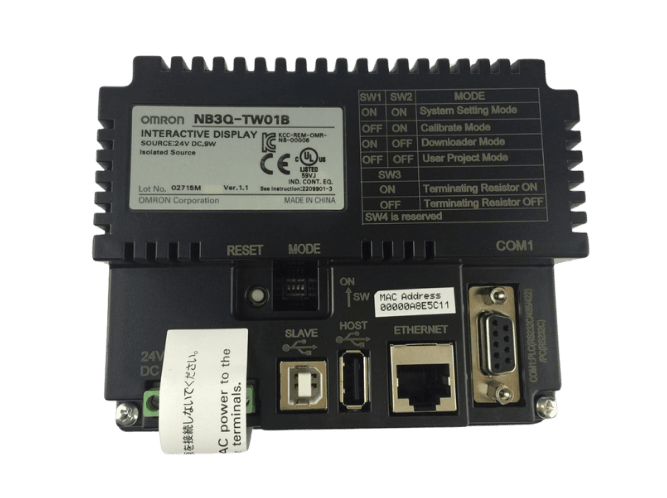

Omron HMI

Omron has established itself as a trusted partner in industrial automation, offering sophisticated HMI solutions that enhance manufacturing productivity and streamline efficiency. Their HMI products combine robust hardware with intuitive interfaces, making them ideal for various industrial applications. The NA Series and NB Series represent Omron's commitment to providing high-performance visualization solutions with the following key features: Advanced touch screen technology, Multiple screen sizes (from 3.5" to wide screen options), TFT display with crystal-clear resolution, Ethernet and serial communication capabilities, Comprehensive PLC compatibility.

How Do Omron HMIs Improve Operational Efficiency?

In modern manufacturing environments, efficiency is paramount. Omron HMIs contribute to operational excellence through:

Enhanced Monitoring Capabilities:

-

Real-time process visualization

-

Customizable alarm systems

-

Trend monitoring and analysis

-

Error logging and troubleshooting

Streamlined Control Features:

-

Direct PLC integration

-

Remote access functionality

-

Advanced programming options

-

Intuitive operator interface

What Are the Key Applications for Omron HMI Products?

Omron HMIs find applications across various industrial sectors

, including:

-

Manufacturing

-

Packaging

-

Food & Beverage

-

Automotive

-

Process control, equipment monitoring

-

Line supervision, quality control

-

Recipe management, hygiene monitoring

-

Assembly line control, testing

Technical Specifications and Features That Matter

The technical capabilities of Omron HMIs include:

Hardware Specifications:

-

TFT LCD displays with multiple size options

-

Industrial-grade touch panels

-

Wide operating temperature range

-

IP65 protection rating

Software Features:

-

Intuitive programming interface

-

Built-in data logging

-

Advanced alarm management

-

Remote monitoring capabilities

Frequently Asked Question

Find answers to common questions about Omron HMI and their functionalities.

While Omron HMIs work best with Omron PLCs, they also support communication with various third-party controllers through multiple protocols including Ethernet/IP and serial communication options.

Consider factors like screen size, required functionality, communication protocols, and environmental conditions.

Omron HMIs support multiple protocols including Ethernet/IP, Serial, and various PLC-specific protocols for seamless integration.

Regular cleaning, backup of project files, and monitoring of system logs are essential maintenance practices.

Omron provides comprehensive training materials, online resources, and technical support for HMI programming and maintenance.

The NB Series offers multiple screen sizes ranging from 3.5 inches to larger wide screen options, with TFT displays providing excellent visibility in industrial environments.

You can backup your HMI application through the programming software, storing both the project files and screen data on a PC or external storage device for safety and maintenance purposes.

Omron HMIs include comprehensive troubleshooting tools such as error logging, alarm history, trend monitoring, and remote diagnostic capabilities for efficient maintenance.

Yes, Omron HMIs support remote access functionality, allowing operators and maintenance personnel to monitor and control the interface from different locations through secure connections.

Regular maintenance should be performed monthly, including screen cleaning, checking connections, reviewing error logs, and ensuring proper environmental conditions are maintained.