Discover how Omron PLCs are revolutionizing industrial automation by ensuring safety and reliability in various applications. This article explores the importance of safety PLCs and how they mitigate risks in industrial settings. It’s a must-read for anyone keen on enhancing safety measures in their automation processes.

What Are Safety PLCs and How Do They Ensure Reliability?

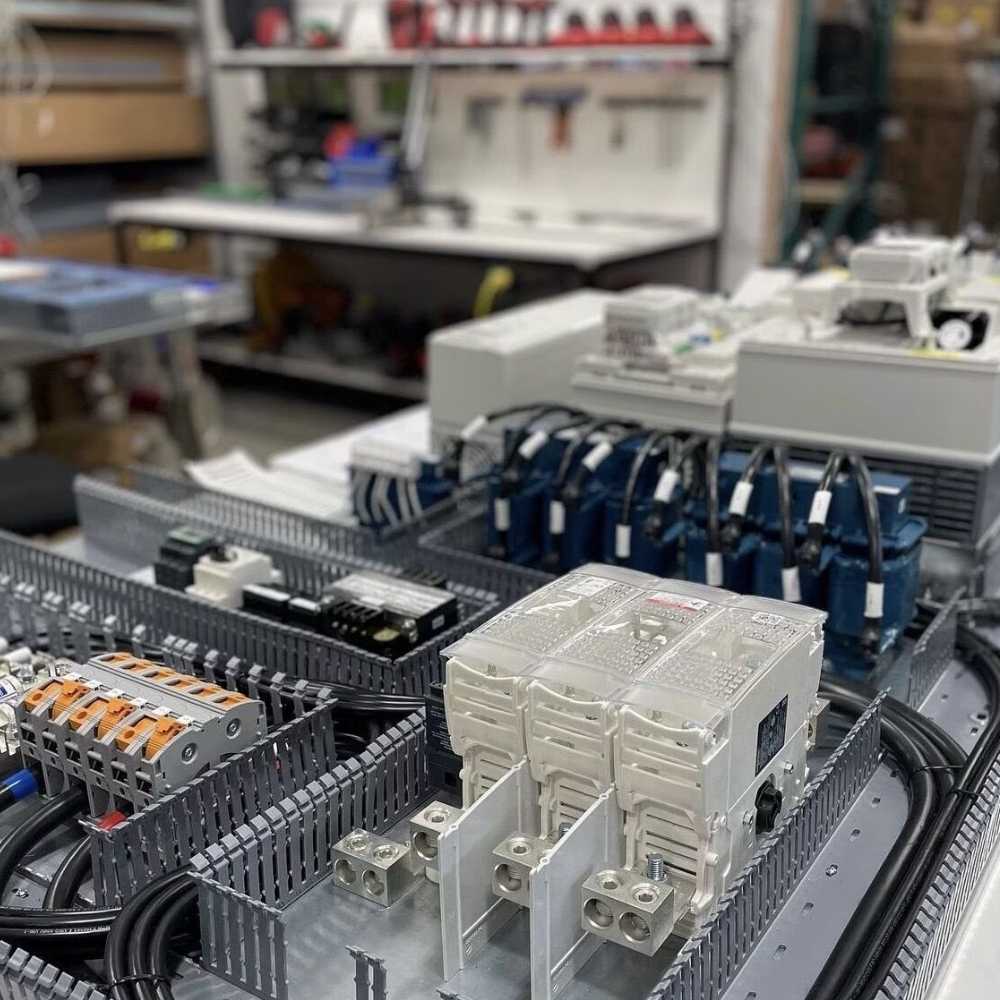

Safety PLCs are specialized programmable logic controllers designed to perform safety-related functions in industrial automation systems. Unlike standard PLCs, safety PLCs adhere to stringent safety standards like IEC 61508, ensuring the safety of workers and equipment.

Key Features of Safety PLCs:

- Redundancy: Incorporates redundant components to prevent failures.

- Built-in Safety Functions: Features like emergency stop and safety interlocks.

- Reliable Operation: Designed to function reliably even during hardware failures.

By utilizing safety PLCs, industries can ensure the safety of their operations, minimizing downtime and preventing accidents. Omron offers a range of safety PLCs that are essential in maintaining safe and reliable industrial processes.

Why Choose Omron Safety PLCs for Industrial Applications?

Omron PLCs stand out in the market due to their commitment to safety and reliability. Here’s why choosing Omron makes a difference:

Advantages of Omron Safety PLCs:

- Compliance with Safety Standards: Meets international safety standards like IEC 61508.

- Robust Control Systems: Offers advanced control systems with built-in safety functions.

- Redundancy and Reliability: Features redundant systems to handle hardware failures effectively.

Incorporating Omron safety PLCs into your industrial automation processes not only enhances safety but also boosts overall system performance. Their safety PLCs ensure that even in the event of a malfunction, operations remain safe.

How Do Safety PLCs Reduce Safety Risks in Industrial Automation?

Implementing safety PLCs is crucial in mitigating safety risks associated with industrial operations. They play a pivotal role in monitoring and controlling industrial processes.

Ways Safety PLCs Reduce Risks:

- Monitoring Safety Functions: Continuously checks for deviations from safe operating conditions.

- Emergency Stop Functions: Allows immediate shutdown during emergencies.

- Safety Interlocks: Prevents hazardous situations by controlling access to dangerous areas.

By using safety PLCs, industries can implement safety measures that ensure the safety of both personnel and equipment. This is particularly important in machinery intensive environments where the risk of accidents is high.

What Safety Measures Should Be Implemented in PLC Systems?

To maximize the benefits of safety PLCs, certain safety measures should be incorporated into PLC systems.

Essential Safety Measures:

- Regular Maintenance: Routine checks to prevent hardware failures and malfunction.

- Proper Wiring: Ensuring all wiring complies with safety protocols.

- Redundancy: Utilizing redundant components to enhance system reliability.

Implementing these measures not only enhances the safety and reliability of the system but also aligns with industry safety standards.

How Do Safety Standards Impact PLC Operations?

Adherence to safety standards like IEC 61508 is critical in industrial automation. These standards guide the design and operation of safety PLCs.

Impact of Safety Standards:

- Improved Safety Protocols: Ensures that safety functions are up to industry expectations.

- Enhanced Reliability: Standards enforce practices that reduce downtime and increase reliability.

- Global Compliance: Facilitates international operations by meeting universal safety requirements.

Omron PLCs are designed with these standards in mind, making them ideal for industries aiming for the highest level of safety.

FAQs

How do safety PLCs differ from standard PLCs?

Safety PLCs are designed with additional safety features and adhere to strict safety standards, offering redundancy and built-in safety functions not typically found in standard PLCs.

Why is redundancy important in safety PLCs?

Redundancy ensures that if one component fails, another can take over, preventing system failures and enhancing overall reliability.

Can Omron safety PLCs help reduce downtime?

Yes, Omron safety PLCs are built to handle hardware failures effectively, thereby reducing downtime and maintaining continuous operations.

What industries benefit most from safety PLCs?

Industries with high-risk machinery operations, such as manufacturing and processing plants, benefit significantly from implementing safety PLCs.

Are Omron PLCs compliant with international safety standards?

Absolutely, Omron PLCs comply with global safety standards like IEC 61508, ensuring they meet international safety requirements.

Conclusion

Ensuring safety and reliability in PLC operations is essential for any industrial setting. Omron safety PLCs provide the necessary features and adhere to strict safety standards, making them an excellent choice for enhancing safety protocols.

Enhance your industrial automation with original Omron products. We offer brand new Omron PLCs, HMIs, Servos, Sensors, Relays, and more at competitive prices. Contact us today for a quotation!