This post explains the challenges and solutions when dealing with a discontinued Omron PLC model. It guides you through assessing your options, whether to convert the existing code or replace the PLC with a newer model, to ensure your industrial automation processes remain efficient and up-to-date. We understand that facing obsolescence can be daunting, but this article aims to provide clarity and actionable insights, making it worth your time.

What are the Challenges of Using Discontinued Omron PLC Models?

When an Omron PLC model is discontinued, it presents several challenges. Firstly, finding replacement parts becomes difficult, if not impossible. This can lead to extended downtime if the PLC fails, as sourcing compatible hardware can take time. Additionally, Omron ceases to provide technical support and software updates for discontinued models. This means you might miss out on new features, security patches, and performance improvements that newer models offer. Using discontinued models can also hinder your ability to integrate with modern automation systems that require newer PLC technology for seamless communication and operation.

Another issue is the lack of compatibility with newer programming software. Older Omron PLCs might only work with outdated software versions, which can be less user-friendly and lack advanced features found in current tools. This makes programming and troubleshooting more time-consuming and potentially more difficult. Furthermore, if your team is not familiar with the older software, it can create a knowledge gap and increase the risk of errors during programming or maintenance. Relying on discontinued models can therefore limit your system’s flexibility and scalability in the long run. Consider exploring omron cj2 series for the latest updates.

How to Identify a Suitable Replacement for a Discontinued Omron PLC?

Identifying a suitable replacement for a discontinued Omron PLC involves evaluating your current system’s requirements and comparing them with the features of newer models. Start by documenting the specifications of your existing PLC, including I/O capacity, memory size, processing speed, and communication protocols. Then, explore Omron’s current product range to find a PLC that meets or exceeds these specifications. For instance, if you were using a C200H, you might consider the CJ or CS1 series as potential replacements.

Once you have identified a few potential candidates, compare their features in detail. Look for models that offer similar or improved functionality, such as faster processing speeds, larger memory capacities, and support for modern communication protocols. It’s also essential to consider the programming software used by the new PLC. Omron’s CX-Programmer is a widely used tool that supports a range of modern PLCs, making it a good choice for future-proofing your system. Additionally, ensure that the new PLC can integrate with your existing hardware and other components of your automation system. Consulting with an Omron representative or a knowledgeable third party can provide valuable insights and help you make an informed decision.

Is it Possible to Convert the Program from an Old Omron PLC to a New One?

Converting a program from an old Omron PLC to a new one is often possible, but it can be a complex process. Omron provides tools like CX-Programmer that include conversion utilities to help with this task. However, the success of the conversion depends on several factors, including the age and complexity of the original program and the differences between the old and new PLC models. It’s crucial to have a backup of your original program before starting the conversion process, and it’s always recommended to thoroughly test the converted program to ensure it functions correctly on the new hardware.

In some cases, a direct conversion might not be feasible, and you may need to rewrite parts of the program. This can be particularly true if the new PLC uses a different programming language or has significantly different hardware specifications. For instance, converting from a C200H to a CP1 series PLC might require manual adjustments due to differences in instruction sets and memory organization. While this can be time-consuming, it also presents an opportunity to optimize the program and take advantage of the new PLC’s features. Thanks for understanding the complexities involved. We agree that Omron’s conversion tools are helpful, but they might not cover every scenario. We appreciate your patience during this process. If you’re interested in the latest in PLC technology, you might want to take a look at the omron cp series.

What are the Costs Associated with Upgrading from a Discontinued Omron PLC?

Upgrading from a discontinued Omron PLC involves various costs, including the price of the new PLC, programming software, and any additional hardware required. While newer PLC models can be more expensive upfront, they often offer better performance and long-term cost savings through improved efficiency and reduced downtime. Additionally, the cost of conversion or rewriting the program should be considered. This can vary depending on the complexity of the program and whether you handle the conversion in-house or hire external expertise.

Beyond the direct costs, there might be indirect expenses related to training your team on the new PLC and software. Investing in training can ensure that your staff can effectively program, operate, and maintain the new system, maximizing its benefits. It’s also worth considering the potential savings from reduced energy consumption and improved productivity that newer PLC models can offer. While the initial investment might seem high, the long-term advantages often outweigh the costs, making it a worthwhile investment for your automation needs. For more details on cost-effective solutions, check out the omron plc supplier.

What Support is Available for Converting Programs and Replacing Discontinued Omron PLC Models?

Omron offers various support options for converting programs and replacing discontinued PLC models. Their website provides access to manuals, software downloads, and technical documentation for their product range. Omron’s technical support team can also offer guidance on selecting a suitable replacement PLC and navigating the conversion process. Additionally, Omron has a network of distributors and partners who can provide local support and expertise. It’s often beneficial to contact the official omron plc supplier for the most accurate and up-to-date information.

In addition to Omron’s resources, online forums and communities can be valuable sources of information and support. Many experienced users share their knowledge and insights on topics related to Omron PLCs, including conversion strategies and troubleshooting tips. Engaging with these communities can provide practical advice and help you learn from others’ experiences. However, it’s important to verify any information obtained from online sources with official documentation or Omron’s technical support to ensure its accuracy and reliability. We recommend exploring these resources to enhance your understanding and wish you success in your endeavors. Thanks for seeking our advice. If you need further assistance, feel free to send us a message. We agree that community support can be very helpful. We appreciate your proactive approach to finding solutions.

FAQs

What should I do if my Omron PLC is no longer supported?

If your Omron PLC is no longer supported, it’s time to consider a replacement. Start by assessing your current system’s requirements and exploring Omron’s current product range to find a suitable model.

Can I use the same program on a new Omron PLC?

In some cases, you can use conversion tools to transfer your program to a new Omron PLC. However, depending on the differences between models, some manual adjustments or rewriting may be necessary. CX-Programmer may be the cheapest solution.

How much does it cost to replace a discontinued Omron PLC?

The cost of replacing a discontinued Omron PLC varies depending on the new model, software, and any additional hardware required. While there are upfront costs, the long-term benefits often outweigh the initial investment.

Where can I find support for converting my Omron PLC program?

Omron’s website provides manuals, software downloads, and technical documentation. Their technical support team and network of distributors can also offer guidance. Additionally, online forums and communities can provide valuable insights.

Is it worth upgrading to a newer Omron PLC model?

Yes, upgrading to a newer Omron PLC model can offer significant benefits, including improved performance, enhanced features, and better integration with modern automation systems. The long-term advantages often justify the initial investment.

What is the first step in replacing a discontinued Omron PLC?

The first step is to document the specifications of your existing PLC and understand your system’s requirements. Then, explore Omron’s current product range to identify potential replacements that meet or exceed your needs.

Conclusion

Dealing with a discontinued Omron PLC model requires careful planning and consideration. Whether you choose to convert your existing program or opt for a complete replacement, the goal is to ensure your automation system remains efficient and up-to-date. By understanding the challenges, exploring your options, and seeking the right support, you can navigate this transition successfully. Consider the omron cj1 series for a reliable upgrade.

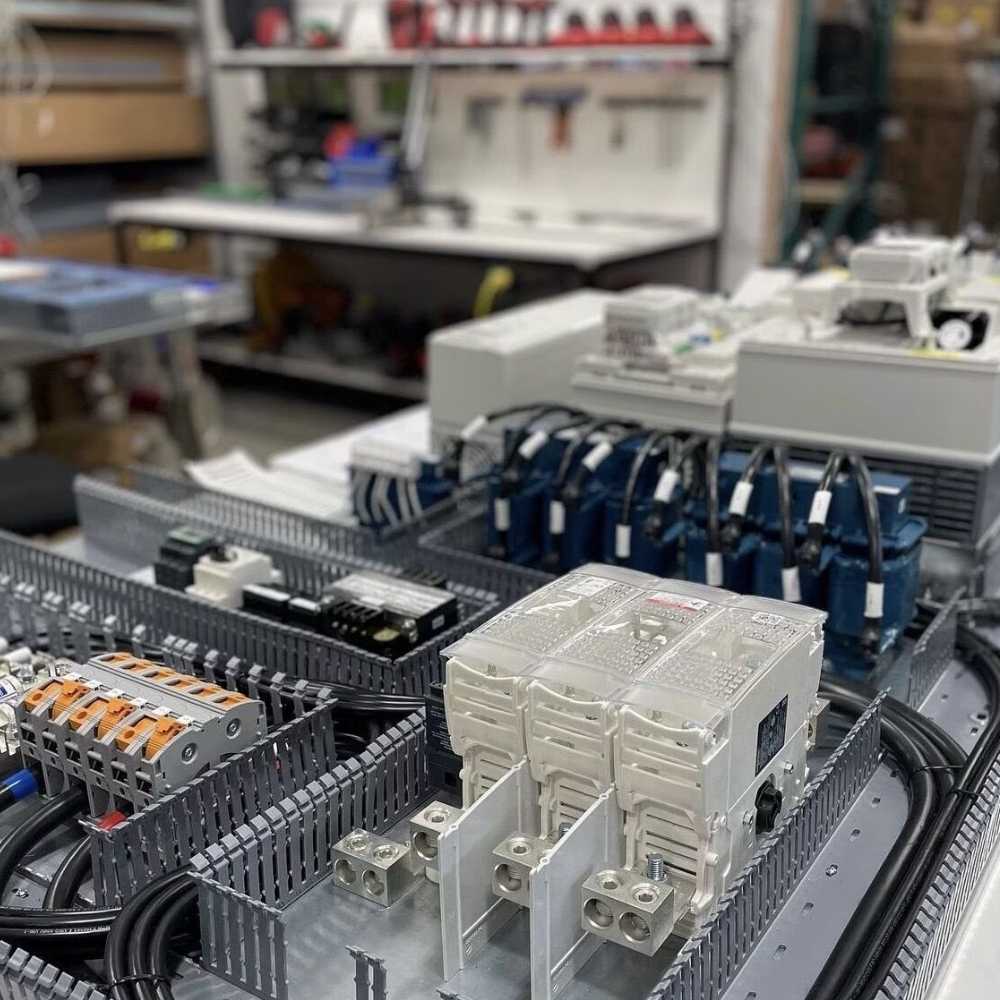

Our company provides brand new and original Omron industrial accessories, including PLC, HMI, Servo, Sensors, and Relay. We offer competitive prices and exceptional service. Contact us today for a quotation and experience the difference. For more details on our product range, visit the omron programmable controller page.