Discover how Omron PLCs leverage various programming languages to revolutionize industrial automation. This comprehensive guide will simplify complex concepts, making it easy for everyone to grasp the essentials of PLC programming and its impact on modern industries.

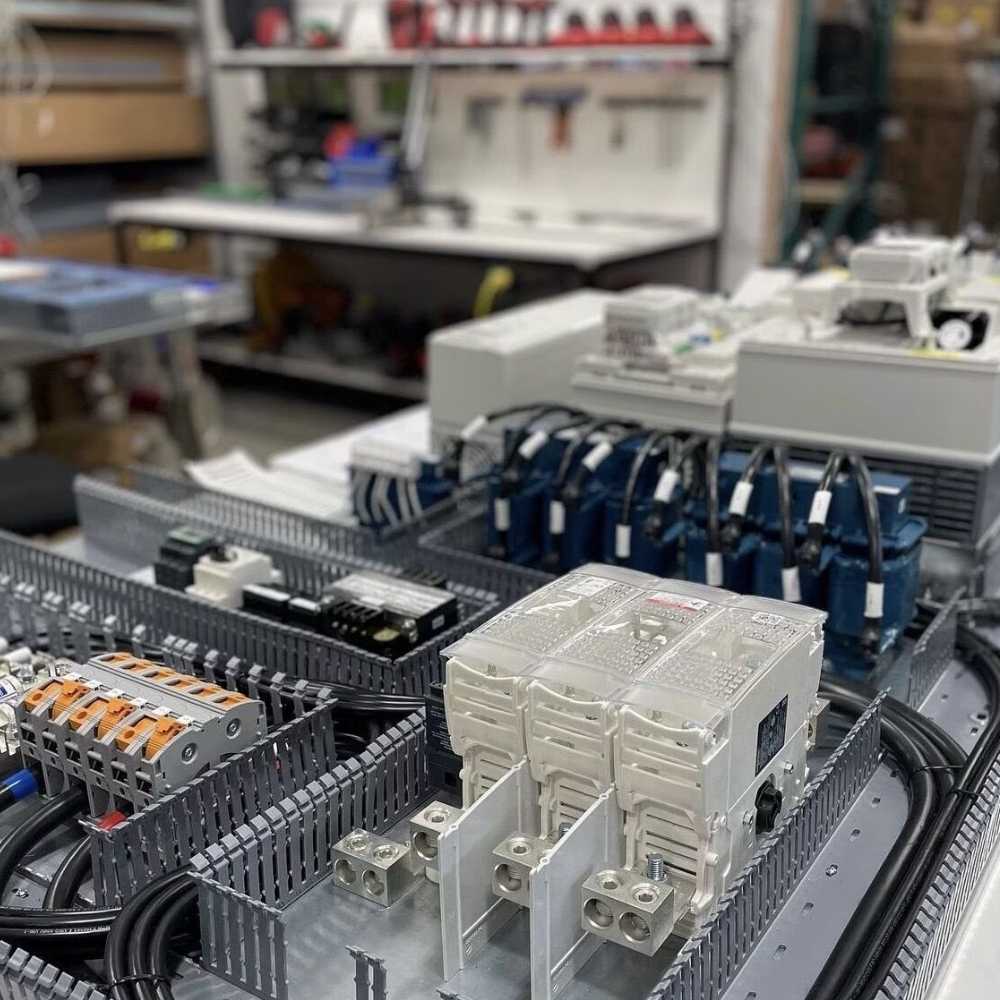

What Is a PLC and Why Is It Vital for Industrial Automation?

A Programmable Logic Controller (PLC) is an industrial computer designed to control machinery and processes in industrial settings. PLCs play a crucial role in automating tasks that were once performed manually, enhancing efficiency and reliability.

Key Features of PLCs:

- Real-time processing capabilities

- Robust control system functions

- Compatibility with various input and output devices

- Support for multiple programming languages

Omron PLCs are renowned for their advanced features and user-friendly interfaces, making them a popular choice in the field of automation.

How Do PLCs Use Programming Languages Like Ladder Logic?

Ladder Logic is a graphical programming language commonly used in PLC programming. It resembles traditional relay logic diagrams, making it easier for engineers familiar with electrical systems to adapt.

Advantages of Ladder Logic:

- Visual Representation: Uses symbols to represent control logic

- Ease of Learning: Intuitive for those with an electrical background

- Widespread Use: Highly adopted in the industry

Omron PLCs support Ladder Logic, allowing for straightforward programming of complex automation tasks.

What Is Structured Text and How Does It Compare to Ladder Logic?

Structured Text is a high-level programming language that resembles traditional programming languages like Pascal or C. It offers more flexibility and is suitable for complex calculations and data processing.

Structured Text vs. Ladder Logic:

| Feature | Ladder Logic | Structured Text |

|---|---|---|

| Type | Graphical | Text-based |

| Ease of Use | Simple for basic control | Better for complex algorithms |

| Learning Curve | Easier for electricians | Easier for programmers |

| Application | Basic control tasks | Advanced programming and data handling |

By offering both Ladder Logic and Structured Text, Omron PLCs cater to a wide range of programming preferences and application needs.

How to Choose the Right PLC Programming Language for Your Project?

Selecting the appropriate programming language depends on your project’s requirements and your team’s expertise.

Factors to Consider:

- Complexity of Control Logic: Use Structured Text for complex algorithms.

- Team’s Skill Set: Choose a language familiar to your programmers.

- Integration Needs: Ensure compatibility with existing systems.

- Future Scalability: Opt for languages that allow for easy expansion.

For beginners, starting with Ladder Logic through an Omron PLC programming tutorial can be an excellent way to dive into the world of PLC programming.

Why Is Understanding PLC Programming Environment Essential?

A solid grasp of the PLC programming environment enhances the efficiency and effectiveness of your automation projects.

Benefits:

- User-Friendly Interface: Simplifies programming and troubleshooting.

- Simulation Tools: Test your PLC programs before deployment.

- Customizable Settings: Tailor the environment to your specific needs.

Omron’s programming software provides a comprehensive platform with tools that support various programming languages, making it easier to manage and control your PLC system.

FAQs

How do PLCs enhance industrial automation?

PLCs offer precise control over machinery and processes, reducing the need for manual intervention and increasing production efficiency in industrial automation.

What programming languages are supported by Omron PLCs?

Omron PLCs support several programming languages, including Ladder Logic, Structured Text, and Function Block Diagram, catering to different programming needs.

Why is Ladder Logic popular in PLC programming?

Ladder Logic is popular due to its intuitive graphical format, which resembles electrical relay logic diagrams, making it accessible for those with an electrical background.

Can I switch between programming languages in Omron PLCs?

Yes, Omron PLCs allow you to use different programming languages within the same project, offering flexibility and adaptability.

How important is the programming environment in PLC programming?

A user-friendly programming environment is crucial as it enhances ease of use, debugging, and overall efficiency in developing PLC programs.

Conclusion

Understanding the programming languages and environment of Omron PLCs is vital for optimizing your automation projects. Whether you’re new to PLC programming or looking to enhance your skills, grasping these concepts will empower you to implement efficient and reliable control systems.

Ready to upgrade your automation setup? Our company offers brand new and original Omron industrial accessories, including PLCs, HMIs, Servos, Sensors, and Relays. The price is competitive—contact us today for a quotation!