Programmable Logic Controllers (PLCs) are the backbone of modern industrial automation. Omron PLCs stand out for their reliability and efficiency in controlling complex automation systems. However, like any sophisticated technology, they require proper maintenance and occasional troubleshooting to ensure they function at their best. This guide provides a comprehensive overview of maintaining and troubleshooting Omron PLC systems to help you minimize downtime and enhance operational efficiency.

What Are the Common Issues Encountered with Omron PLCs?

Understanding the typical problems that can arise with PLC hardware is essential for effective troubleshooting.

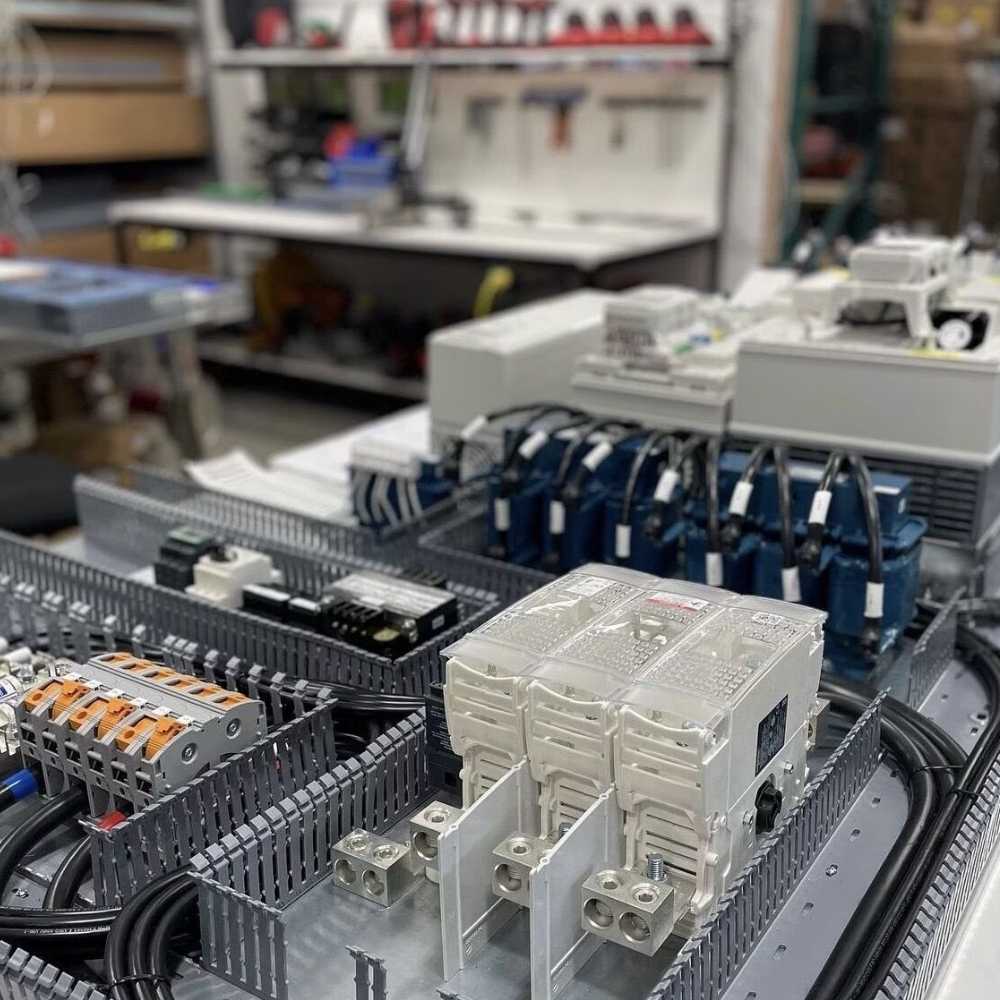

Hardware Failure and Loose Connections

One of the most common issues is hardware failure due to wear and tear or environmental factors. Components like power supplies and CPUs can be affected by:

- Electrical interference: Can cause the PLC to malfunction.

- Temperature and humidity ranges: Operating outside recommended levels may lead to hardware failure.

- Loose connections: May disrupt the power to the PLC, affecting its performance.

It’s crucial to inspect your PLC hardware regularly to spot any signs of damage or loose connections.

Input and Output Module Issues

Problems with input and output modules can lead to incorrect data processing:

- Faulty input modules: May prevent the PLC from receiving accurate signals.

- Defective output modules: Can cause issues in executing commands.

Regular testing ensures that your input and output modules are functioning correctly.

How to Diagnose and Troubleshoot PLC Systems Effectively?

Proper diagnosis is the first step in resolving PLC issues. Here’s a step-by-step guide to help diagnose problems effectively.

Step 1: Perform a Visual Inspection

Begin by examining the PLC system for any obvious issues:

- Check for physical damage: Look for burnt components or damaged wiring.

- Verify connections: Ensure all components are correctly connected and secure.

- Assess environmental conditions: Make sure the PLC is operating within the recommended temperature and humidity ranges.

Step 2: Use Diagnostics Tools

Utilize the PLC’s built-in diagnostics features:

- Error codes: Refer to the manual to interpret any displayed codes.

- Logs to identify: Check system logs for any irregularities.

- Firmware updates: Ensure that the PLC’s firmware is up-to-date to prevent issues caused by outdated firmware.

Step 3: Test Input and Output Modules

- Measure the voltage across input and output modules to confirm they are receiving the correct power supply voltage.

- Replace modules if the module is faulty and need to be replaced.

By following these steps, you can efficiently diagnose and address any problems within your PLC system.

Why Is Regular Maintenance Crucial for PLC Systems?

Routine regular maintenance of your Omron PLCs is vital for ensuring optimal performance and extending the life of your equipment.

Preventative Maintenance Benefits

- Minimize downtime: Regular checks help minimize downtime caused by unexpected failures.

- Ensure stability: Maintaining components prevents electrical noise and electrical interference from entering the system.

- Improve performance: Keeping the system clean and components in good condition can improve performance of a PLC.

Maintenance Activities

- Inspect and maintain: Regularly inspect the PLC hardware for wear and tear.

- Firmware updates: Keep the PLC’s firmware and software up-to-date.

- Proper installation: Ensure that any new components are installed correctly to avoid future issues.

Regular maintenance tasks are simple but must be completed consistently to be effective.

What Are the Best Practices for Proper PLC Installation?

Ensuring a correct PLC installation is fundamental for smooth operation and preventing potential problems.

Selecting the Right Environment

- Temperature and humidity: Install the PLC in areas within specified temperature and humidity ranges.

- Avoid electrical interference: Keep the PLC away from devices that may cause electrical noise.

Proper Wiring and Grounding

- Grounding: Proper grounding is essential to prevent electrical interference.

- Quality cabling: Use high-quality cables to ensure proper signal transmission.

Configuration and Compatibility

- Configure the system according to manufacturer guidelines.

- Ensure compatibility of all components within the PLC network.

Following these practices helps in maintaining the performance of a PLC and reducing operational issues.

Where Can You Find Technical Support and Ask for a Quote?

When in need of assistance, knowing where to turn is crucial.

Omron’s Technical Support

- Omron offers extensive technical support for their products.

- Access to resources for troubleshooting PLC systems and updates.

Reliable Suppliers

- Consider Omron Industrial Automation for authentic products.

- For inquiries and purchases, you can ask for a quote to get competitive pricing.

By partnering with trusted suppliers, you ensure you receive genuine products and support.

Frequently Asked Questions

How often should I perform maintenance on my Omron PLC?

It’s recommended to conduct regular maintenance every six months, but critical systems may require more frequent checks to ensure optimal performance.

What are the signs of a faulty PLC module?

Signs include unexpected downtime, error messages, and inconsistent input and output signals. A module is faulty if it fails to respond during tests.

Can outdated firmware affect my PLC’s performance?

Yes, outdated firmware can lead to operational issues. Keeping firmware up-to-date ensures the PLC operates with the latest improvements.

How do I prevent electrical noise from affecting my PLC?

Proper grounding and shielding of cables can prevent electrical noise from entering the system, protecting the PLC from electrical interference.

What support does Omron provide for troubleshooting?

Omron offers comprehensive technical support including manuals, online resources, and customer service to assist with diagnosing and repairing PLC issues.

Conclusion

Maintaining and troubleshooting your Omron PLCs is essential for the smooth operation of your automation systems. By understanding common issues and following best practices for maintenance and installation, you can ensure your PLCs perform optimally, reducing downtime and enhancing productivity.

Our company provides brand new and original Omron industrial accessories, including PLCs, HMIs, Servos, Sensors, and Relays. Our prices are competitive—contact us today for a quotation.