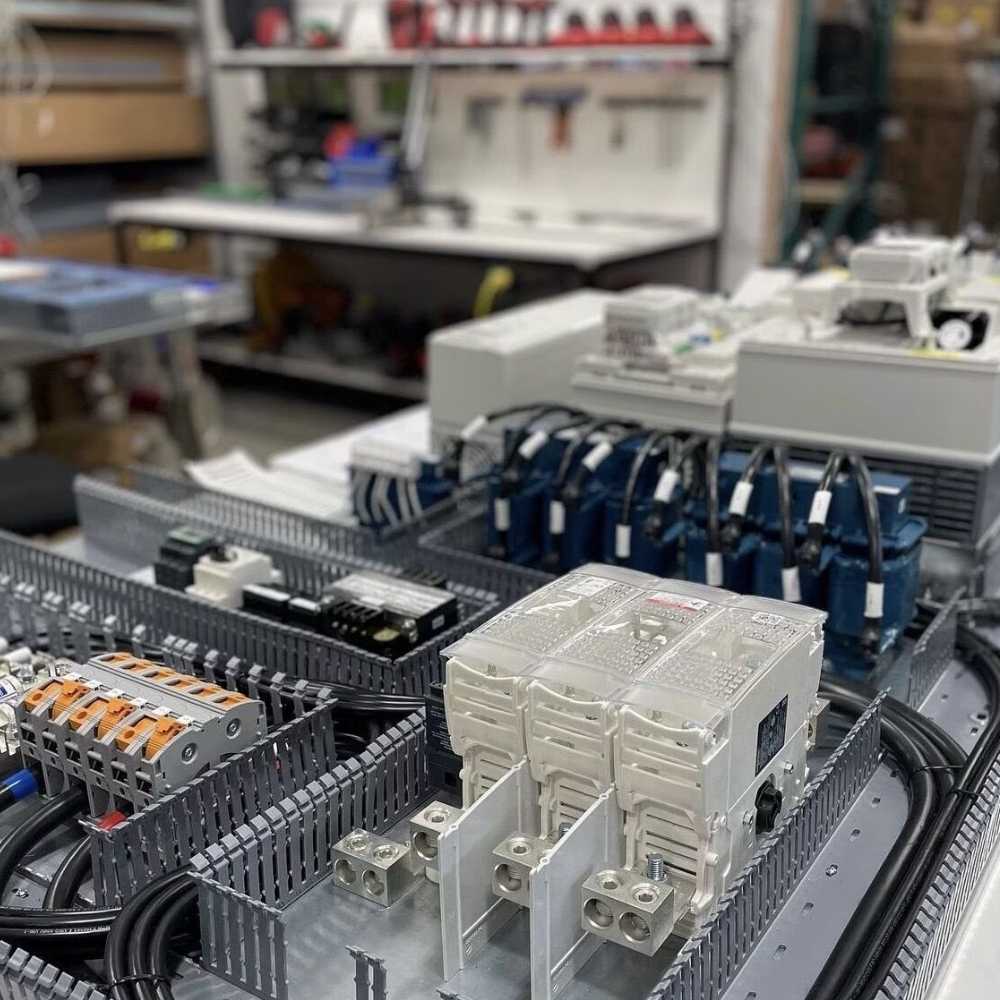

Discovering how to effectively troubleshoot communication problems in Omron PLCs can significantly enhance your industrial automation processes. This comprehensive guide delves into common issues and offers practical solutions, making it an essential read for anyone looking to optimize their PLC communication systems.

What Causes PLC Communication Problems in Omron Devices?

Communication issues in Programmable Logic Controllers (PLCs), especially those from Omron, can stem from various factors. Identifying these causes is the first step toward efficient troubleshooting.

Hardware Connectivity Issues

One of the primary culprits is faulty or improperly connected Ethernet cables. It’s crucial to ensure that all cables are securely connected and in good condition. Inspect the connectors for any signs of wear or damage that could lead to communication errors.

Incorrect Communication Settings

Misconfigured communication settings such as IP addresses, communication protocols, and port numbers can prevent the PLC from communicating effectively with other network devices. Verifying these parameters aligns with your network requirements is essential.

Faulty Ethernet Cards and Ports

A malfunctioning Ethernet card or port within the PLC or connected devices can disrupt communication. Regularly inspect and, if necessary, replace these components to maintain reliable communication channels.

How to Ensure Reliable Ethernet Connections for Omron PLCs

Establishing a stable Ethernet connection is vital for the seamless operation of your Omron PLCs. Here are some strategies to ensure robust connectivity.

Use High-Quality Ethernet Cables

Invest in high-quality Ethernet cables that meet industrial standards. This helps in minimizing interference and network traffic issues, leading to reliable communication between your PLC and other devices.

Configure Network Adapters Correctly

Proper configuration of your network adapter settings is crucial. This includes setting the correct IP address, subnet mask, and default gateway to match your network’s configuration. Utilizing the appropriate communication protocol like Modbus or Profinet is also essential.

Regular Maintenance and Inspection

Routine checks and maintenance of your network hardware can prevent unforeseen downtime. Regularly inspect all hardware components, including switches and routers, to ensure that your PLC network operates smoothly.

Troubleshooting Common Communication Protocol Issues

Communication protocols are the backbone of PLC communication. Understanding and troubleshooting these protocols can resolve many communication problems.

Verifying Communication Protocol Settings

Incorrect settings can lead to communication errors. Verify that the PLC and all connected devices are configured to use the same communication protocol. Mismatched settings can cause the devices to fail to communicate.

Updating Firmware and Software

Outdated firmware and software can lead to compatibility issues. Regular updates from the manufacturer—in this case, Omron—can provide fixes for known issues and enhance performance.

Addressing Compatibility with Multiple Devices

When integrating PLCs with devices from different brands like Mitsubishi or Schneider, compatibility can be a hurdle. Ensure that all devices support the chosen communication protocol and settings.

Setting Up Communication Parameters: Ports, IP Addresses, and More

Accurate configuration of communication parameters is essential for the PLC to interact correctly with other devices.

Configuring IP Addresses and Ports

Assign a unique IP address to each PLC and device on the network. Configure the correct port numbers to match the communication protocol in use. This prevents address conflicts and facilitates proper routing of data.

Adjusting Communication Settings

Fine-tuning settings like baud rate, communication protocol, and timeout values can optimize data transfer. Ensure that these settings are consistently applied across all devices in the network.

Synchronizing Communication Parameters

All devices must have synchronized communication parameters. Mismatches can lead to data loss or communication errors. Regular audits of these settings help in maintaining network integrity.

Best Practices to Optimize Omron PLC Network Performance

Implementing best practices can prevent communication problems and enhance overall system efficiency.

Utilize Manufacturer Guidelines

Always adhere to Omron’s manufacturer guidelines for installation and configuration. This ensures that you’re following recommended procedures that are tailored for Omron’s devices.

Monitor Network Traffic

Using specialized tools to analyze network traffic helps in identifying bottlenecks and potential issues. By monitoring the network, you can detect and address problems before they escalate.

Regular Training and Technical Support

Investing in training for your technical team ensures they are equipped to handle PLC communication issues effectively. Additionally, utilizing Omron’s technical support can provide insights and solutions to complex problems.

Frequently Asked Questions

How do I reset the communication settings on my Omron PLC?

To reset the communication settings, you can use the PLC’s programming software to restore default settings. Make sure to back up existing configurations before proceeding.

Can I use third-party Ethernet cables with Omron PLCs?

Yes, but it’s important to use high-quality, compatible Ethernet cables to prevent interference and ensure reliable communication.

What should I do if my PLC is not recognizing the Ethernet card?

First, inspect the Ethernet card for any physical damage. If the hardware is intact, check the configuration settings to ensure it’s properly installed and recognized by the PLC.

How can I improve the network security of my PLC communication?

Implementing network security protocols, such as firewalls and secure communication protocols, can protect against unauthorized access and data breaches.

Is it possible to connect Omron PLCs with devices from other manufacturers like Mitsubishi?

Yes, by using standard communication protocols like Modbus, you can facilitate communication between Omron PLCs and devices from other brands.

Conclusion

Effectively troubleshooting and optimizing communication in Omron PLCs is crucial for maintaining efficient and reliable industrial automation systems. By understanding common issues and implementing best practices, you can minimize downtime and enhance productivity.Ready to optimize your Omron PLC systems? Our company offers brand new, original Omron industrial accessories, including PLCs, HMIs, Servos, Sensors, and Relays at competitive prices. Contact us now for a quotation!