Understanding the world of Omron PLC (Programmable Logic Controller) is essential for anyone interested in industrial automation. This article offers a clear and concise introduction to the basics of Omron PLC programming, guiding you through fundamental concepts in an accessible way. Whether you’re a beginner or looking to refresh your knowledge, this read will equip you with valuable insights.

What is Omron PLC and Why is it Essential in Industrial Automation?

An Omron PLC is a specialized piece of hardware used to control machinery and processes in industrial settings. Think of it as the brain of an automation system, making decisions based on the inputs it receives. By using an Omron PLC, industries can perform tasks more efficiently, reduce errors, and adapt quickly to changing production needs.The importance of Omron PLCs in industrial automation cannot be overstated. They provide a flexible and reliable method to manage complex systems. Industries like manufacturing, automotive, and energy rely on these controllers to keep operations running smoothly. By embracing Omron PLCs, companies are able to:

- Control intricate machinery with precision

- Automate repetitive tasks to increase productivity

- Reduce downtime through efficient programming

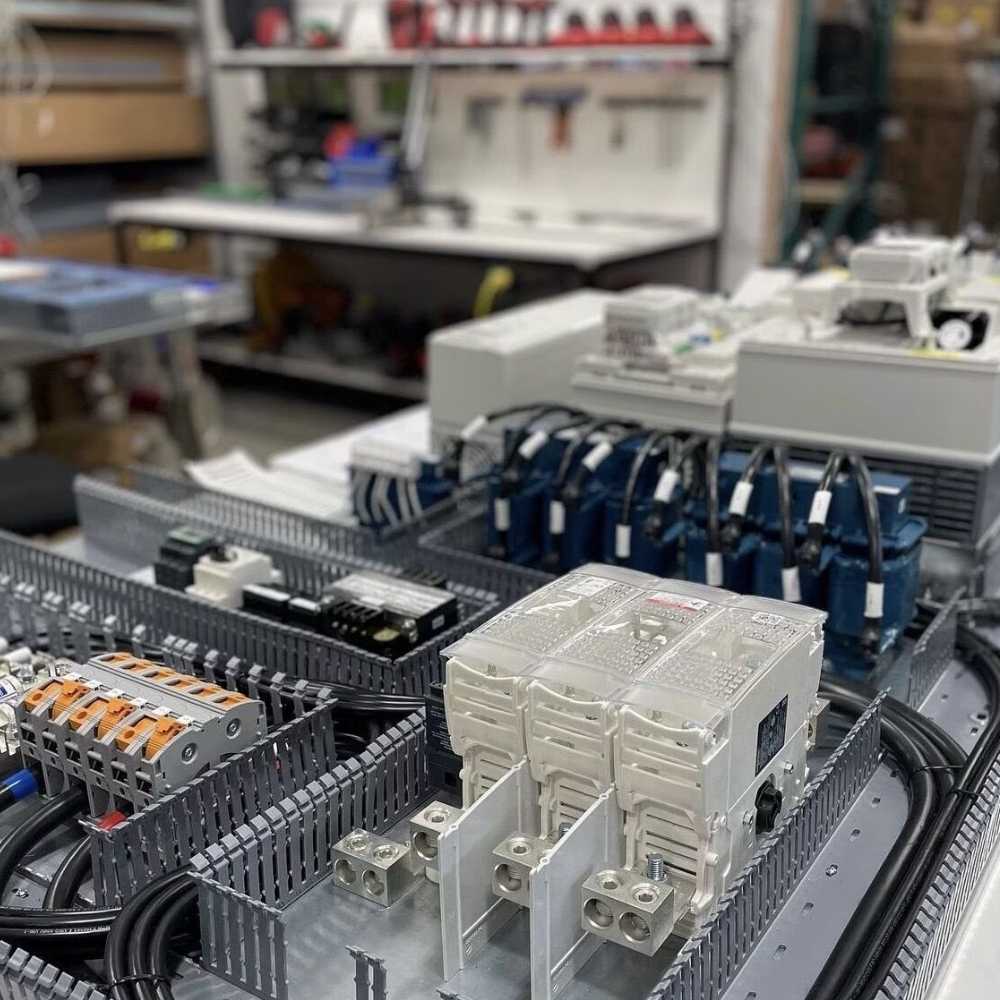

Unable to render image

An engineer programming an Omron PLC

How Can Automation Engineers Get Started with Omron PLC Programming?

If you’re an automation engineer eager to dive into Omron PLC programming, you’re in the right place. Getting started is simpler than you might think. First, it’s important to develop a basic understanding of how programmable logic controllers work and how they interact with industrial equipment.Begin by familiarizing yourself with the core components:

- Input and Output Modules: These handle the signals coming in and out of the PLC.

- CX-Programmer Software: Omron’s dedicated software for PLC programming.

- Ladder Logic: The primary language used for programming PLCs.

To get started, consider enrolling in a training course that provides hands-on experience. For instance, the CP1L-M40DT1-D PLC Controller is a great entry-level device for beginners. These courses often cover:

- Understanding basic concepts of PLCs

- Learning to design simple programs

- Practicing with real-world examples

By embarking on this learning journey, you’ll understand how to program and control automation systems effectively.

The Fundamentals of Omron PLC Training: Learning Ladder Logic

At the heart of Omron PLC programming lies ladder logic, a visual programming language resembling the rungs of a ladder. It’s designed to be intuitive, especially for those with an electrical background. Learning ladder logic is crucial because it forms the foundation of most PLC programs.In your training, you’ll encounter key elements like:

- Contacts and Coils: Representing inputs and outputs in the program.

- Timers and Counters: Managing time-based operations and event counts.

- Instruction Sets: Predefined commands that perform specific functions.

For example, if you want to control a motor to run for a specific duration, you’ll use a timer in your ladder logic program. Similarly, a counter can track how many products have passed a certain point on a conveyor belt.Understanding these components allows you to design programs that perform complex tasks with simplicity. Practical examples and regular testing are vital to grasp these concepts fully.

Key Components in Ladder Logic:

- Inputs/Outputs: Initiate and receive signals.

- Timers: Delay or extend actions.

- Counters: Keep track of events.

- Functions: Execute specific operations.

Online Courses and Resources to Learn Omron PLC Programming

In today’s digital age, you have the advantage of accessing a wealth of online training resources. These platforms provide flexibility, allowing you to learn at your own pace. Whether you’re a beginner or seeking advanced knowledge, there’s something for everyone.Popular Online Resources:

ResourceDescriptionCostOmron’s Official Training ModulesComprehensive guides on Omron PLC programmingFreeOmron PLC SupplierOffers tutorials and latest Omron PLC modelsFree/PaidIndustrial Automation ForumsCommunity discussions, tips, and troubleshootingFreePLC Programming Courses on Educational PlatformsStructured courses with certification optionsPaid

These resources often include:

- Interactive instruction videos

- Practical examples and tests

- Access to software like CX-Programmer

By utilizing these tools, you’ll be able to get a solid grasp of Omron PLCs and ladder logic without the constraints of traditional classrooms.

Joining the Automation Community: Sharing Knowledge and Insights

Becoming part of the automation community is a fantastic way to enrich your learning experience. Engaging with peers allows you to share ideas, ask questions, and stay updated on the latest industry trends.Ways to Get Involved:

- Participate in online forums and discussion groups.

- Attend webinars and virtual conferences.

- Join professional networks focused on industrial automation.

For instance, exploring products like the CJ1W-OD263 Transistor Output Unit can spark conversations and lead to collaborative projects.Quote from an Industry Expert:”By connecting with others, we not only enhance our own understanding but also contribute to the growth of the entire automation field.”Being active in the community helps you keep abreast of new technologies and methodologies, ensuring you remain at the forefront of the industry.

Practical Applications of Omron PLCs in Industrial Settings

Understanding theory is one thing, but seeing how Omron PLCs are applied in real-world scenarios brings the learning full circle. These controllers are integral in various sectors, performing tasks that require precision and reliability.Common Applications:

- Manufacturing Lines: Coordinating machinery for assembly and packaging.

- Energy Management: Controlling power distribution and monitoring usage.

- Process Control: Regulating conditions like temperature and pressure in chemical plants.

For those interested in hands-on experience, products like the CJ2M-CPU34 CPU Unit offer advanced features for complex systems.By exploring these applications, you’ll know how the concepts you’ve learned translate into tangible outcomes, enhancing your ability to design effective automation solutions.

Frequently Asked Questions

What is an Omron PLC used for?

An Omron PLC is used to control industrial machinery and processes. It acts as the brain of an automation system, executing programmed instructions to manage equipment efficiently.

How can I start learning Omron PLC programming?

You can start by enrolling in a training course or utilizing online training resources that provide tutorials on the basics of PLC programming, including ladder logic and the CX-Programmer software.

What is ladder logic in PLC programming?

Ladder logic is a visual programming language that resembles a ladder. It’s used in PLC programming to create control programs that the PLC can execute to manage industrial processes.

Are there free resources available to learn Omron PLC programming?

Yes, there are many free resources available, such as online tutorials, manuals, and forums where you can access information and learn at your own pace.

Why should I consider using Omron PLCs over others?

Omron PLCs are known for their reliability, versatility, and user-friendly interfaces. They provide robust solutions for various industrial applications, making them a popular choice among automation professionals.

Can I program an Omron PLC without prior experience?

While prior experience is helpful, Omron PLCs are designed to be approachable for beginners. With the right training and resources, anyone can learn to program an Omron PLC.

Conclusion

Embarking on the journey to understand Omron PLCs is both rewarding and beneficial. With dedication and the right resources, you can master the basics of PLC programming and make significant contributions to the field of industrial automation.To support your automation needs, our company offers brand new and original Omron industrial accessories, including PLCs, HMIs, Servos, Sensors, and Relays. Our prices are competitive. Contact us today for a quotation!