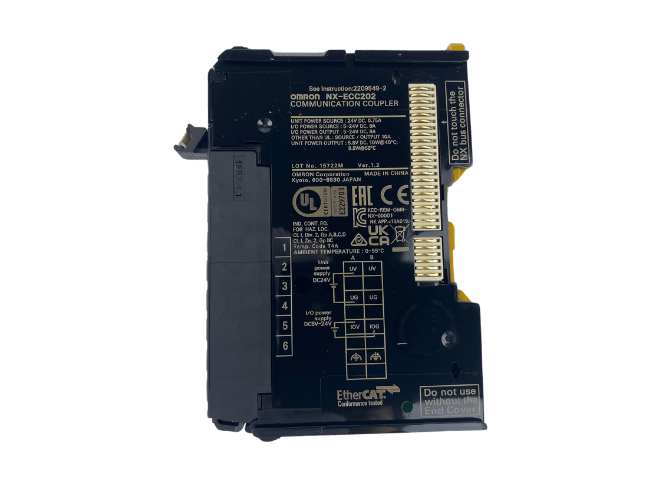

Omron NX Series

The Omron NX Series represents a significant leap forward in industrial automation technology, combining advanced control capabilities with unprecedented flexibility and safety features. The Omron NX Series stands at the forefront of industrial automation by enabling manufacturers to operate with greater productivity and streamlined efficiency. Advanced Control Features: High-speed processing capabilities, Integrated safety controls, Flexible configuration options.

Enhanced Connectivity: EtherCAT communication, Seamless system integration, Multiple interface options.

What Makes the NX Series Perfect for Industry 4.0?

The NX Series is designed to meet the demands of modern manufacturing environments by offering:

Integrated Safety Control

- Built-in safety functions

- Real-time monitoring capabilities

- Comprehensive diagnostic features

Advanced Motion Control

- Multiple axes control

- Precise positioning

- Synchronized motion capabilities

How Does the System Architecture Enhance Performance?

The system architecture of the NX Series is built around:

CPU Units

- High-processing speed

- Multiple programming options

- Integrated motion control

Power Supply Units

- Reliable power distribution

- Built-in protection features

- Efficient power management

What Are the Key Integration Benefits?

The NX Series offers several integration advantages:

Communication Capabilities

- EtherCAT network support

- Multiple protocol options

- Seamless device connectivity

System Flexibility

- Wide variety of I/O options

- Scalable architecture

- Easy maintenance features

Frequently Asked Question

Find answers to common questions about Omron NX Series and their functionalities.

The Omron NX Series is a modular I/O system designed for high-speed and high-precision control in industrial automation. It features advanced control capabilities, integrated safety functions, and flexible configuration options, making it ideal for modern manufacturing environments.

The NX Series enhances efficiency by enabling manufacturers to operate with greater productivity and streamlined efficiency through its high-speed processing capabilities and synchronized data collection. This allows for precise control and improved operational performance.

The NX Series includes built-in safety functions such as real-time monitoring and comprehensive diagnostic features, supporting two industrial safety networks for industrial robot systems. This integration enhances safety compliance and reduces system complexity.

Yes, the NX Series offers multiple communication protocols like EtherCAT and interfaces that allow for seamless integration with existing systems. Its scalable architecture and wide variety of I/O options facilitate easy expansion and maintenance.

Industries such as packaging, robotics, and general manufacturing that require precise control and safety integration can greatly benefit from the NX Series. Its advanced motion control and flexibility make it suitable for various industrial applications.

The NX Series supports Industry 4.0 by providing a unique control system that enables data synchronization collection and flexible system configuration, leading to quality improvement and enhanced connectivity.

The NX Series supports multiple axes control, precise positioning, and synchronized motion capabilities, allowing for advanced motion control in complex automation tasks.

The NX Series stands out due to its combination of high-speed processing, integrated safety features, and advanced motion control in a single platform. It allows for efficient and flexible automation solutions.

The modular design of the NX Series allows for easy maintenance with features like hot-swappable I/O units and comprehensive diagnostics, reducing downtime and maintenance costs.

Yes, the NX Series includes temperature control units like the NX-TC, which optimize control by detecting status changes and satisfy both productivity and quality requirements.