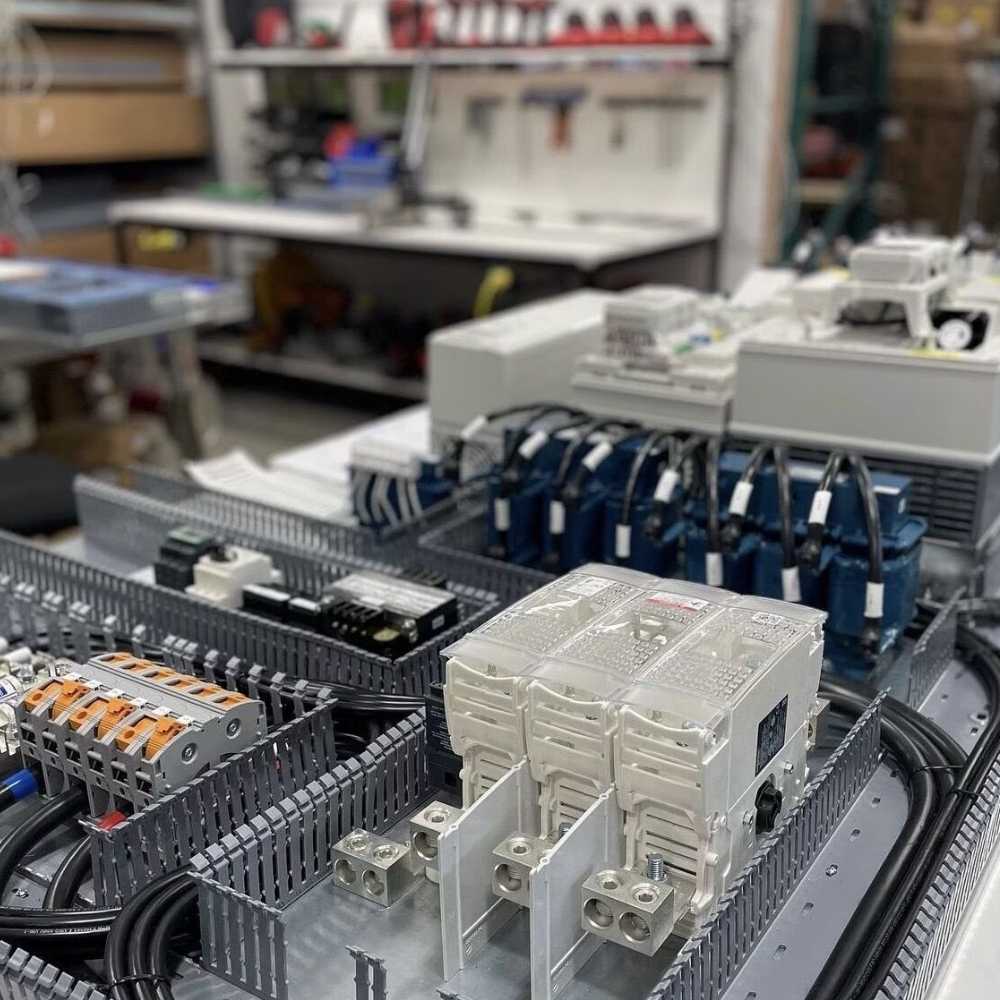

Are you considering enhancing your industrial processes with advanced automation? Implementing a SCADA system with Omron PLCs could be the solution you’ve been searching for. This guide simplifies the integration of SCADA software with Omron Programmable Logic Controllers, helping you streamline operations and boost efficiency. Let’s delve into how you can harness this technology in your industry.

What is SCADA and How Does It Work with Omron PLCs?

Understanding SCADA and its interaction with Omron PLCs is the first step toward successful implementation.

Understanding SCADA Systems

SCADA stands for Supervisory Control and Data Acquisition. It’s a system used for monitoring and control in various industrial applications.

- Data Acquisition: Collects data from sensors and instruments attached to machinery.

- Supervisory Control: Allows operators to control processes remotely.

- Visualization: Presents data in an understandable format via Human-Machine Interfaces (HMIs).

Integration with Omron PLCs

Omron PLCs act as the programmable logic controllers that interact with the machinery.

- Data Exchange: Omron PLCs send and receive data to the SCADA system.

- Process Control: They execute the control actions determined by the SCADA software.

- Seamless Communication: Utilizing protocols like Ethernet and Modbus, they ensure reliable connectivity.

By combining SCADA with Omron PLCs, you create a robust automation platform that enhances control and efficiency. For more on Omron’s PLCs, visit our Omron PLCs page.

Why Choose Omron PLCs for Your SCADA System?

Selecting the right PLCs is crucial for the success of your SCADA system. Here’s why Omron PLCs stand out.

Reliability and Performance

Omron is renowned for producing high-quality PLCs that offer:

- Robust Performance: Handles complex processes with ease.

- Reliability: Minimizes downtime in critical operations.

- Scalability: Adapts to the growing needs of your industry.

Compatibility with SCADA Software

Omron PLCs seamlessly integrate with various SCADA software platforms.

- OPC UA Protocol: Supports Open Platform Communications Unified Architecture for standardized communication.

- Flexible Connectivity: Works with multiple protocols like Modbus and Ethernet/IP.

- Easy Programming: Simplifies PLC programming with user-friendly interfaces.

Industry Applications

Omron’s solutions are ideal for diverse industries:

- Automotive

- Manufacturing

- Energy and Utilities

Choosing Omron PLCs ensures your SCADA system operates efficiently across various applications.Explore our range of Omron CP Series PLCs for reliable performance.

How to Set Up Communication Protocols Between SCADA and Omron Controllers?

Establishing effective communication is vital for your SCADA system to function correctly with Omron controllers.

Understanding Communication Protocols

Protocols define how data is transmitted between devices.

- Modbus: A widely used protocol in industrial automation.

- OPC UA: Enables secure and reliable data exchange.

- Ethernet/IP: Provides high-speed connectivity.

Steps to Configure Communication

- Select the Protocol: Choose a protocol supported by both your SCADA software and Omron PLC.

- Configure Network Settings:

- Set IP addresses.

- Define subnet masks.

- Program the PLC:

- Use PLC programming software like Sysmac Studio.

- Programme communication instructions.

- Set Up SCADA Software:

- Define communication channels.

- Map data points to the database.

Tips for Seamless Communication

- Consistency: Ensure protocol settings match on both ends.

- Testing: Validate the connection with test data.

- Documentation: Keep records of configurations for troubleshooting.

By carefully setting up communication protocols, you enhance the reliability of your SCADA system.For assistance with programming, check out our Omron Programmable Controller resources.

Step-by-Step Guide to Programming Omron PLCs for SCADA Integration

Programming your Omron PLC correctly is essential for integration with your SCADA system.

Tools You’ll Need

- PLC Programming Software: Sysmac Studio or CX-One.

- SCADA Software: Compatible platforms like Indusoft or Wonderware.

- Communication Cables: For connecting your PC to the PLC.

Programming Steps

- Define I/O Points:

- Identify inputs (sensors) and outputs (actuators).

- Write the Program:

- Use ladder logic or structured text.

- Implement control logic for your processes.

- Configure Communication Settings:

- Set up the communication protocol.

- Define data blocks for exchange.

- Test the Program:

- Simulate operations within the software.

- Check for errors or bugs.

- Download to PLC:

- Transfer the programme to the PLC.

- Monitor execution in real-time.

Best Practices

- Modular Programming: Break down tasks into functions for easier management.

- Comments and Documentation: Annotate your code for clarity.

- Firmware Updates: Keep your PLC firmware current.

By following these steps, you ensure your Omron PLC is ready for seamless integration with your SCADA system.Need programming software?

Enhancing Industrial Automation with Omron PLCs and SCADA Connectivity

Combining Omron PLCs with a SCADA system elevates your industrial automation capabilities.

Benefits of Integration

- Real-Time Monitoring: Access live data from your processes.

- Improved Control: Adjust parameters on-the-fly for optimal performance.

- Data Analysis: Utilize historical data for decision-making.

Leveraging Advanced Technologies

- IIoT Integration: Connect to the Industrial Internet of Things for enhanced connectivity.

- Cloud Computing: Store and analyze data on cloud platforms.

- Artificial Intelligence: Implement predictive maintenance and optimization.

Case Study: Successful Implementation

An automotive manufacturer integrated Omron PLCs with a SCADA system, resulting in:

- 20% Increase in Efficiency

- 15% Reduction in Downtime

- Enhanced Visibility across the production line

By embracing these technologies, you position your operations at the forefront of industrial innovation. Learn more about Omron Industrial Automation solutions.

Frequently Asked Questions

What is the role of an HMI in a SCADA system with Omron PLCs?

An HMI (Human-Machine Interface) allows operators to interact with the SCADA system, providing visualization and control over the processes managed by Omron PLCs.

Can I use different SCADA software platforms with Omron PLCs?

Yes, Omron PLCs are compatible with various SCADA software platforms, especially those supporting standard protocols like OPC UA and Modbus.

How does OPC UA enhance communication in SCADA systems?

OPC UA (Open Platform Communications Unified Architecture) offers a secure and reliable framework for data exchange between PLCs and SCADA systems, enhancing interoperability.

Do I need expert programming skills to implement a SCADA system with Omron PLCs?

While basic knowledge of PLC programming is helpful, user-friendly software like Sysmac Studio makes it accessible. Additionally, resources and support are available to assist you.

What industries benefit the most from integrating SCADA systems with Omron PLCs?

Industries such as manufacturing, energy, water treatment, and automotive benefit greatly by improving efficiency, control, and data management.

Conclusion

Implementing a SCADA system with Omron PLCs is a strategic move to elevate your industrial automation processes. By understanding the integration steps and leveraging advanced technologies, you can achieve greater efficiency, control, and insight into your operations.

Looking to implement a SCADA system with Omron products? We provide brand new and original Omron PLCs, HMIs, Servos, Sensors, and Relays at competitive prices. Contact us for a quotation today!