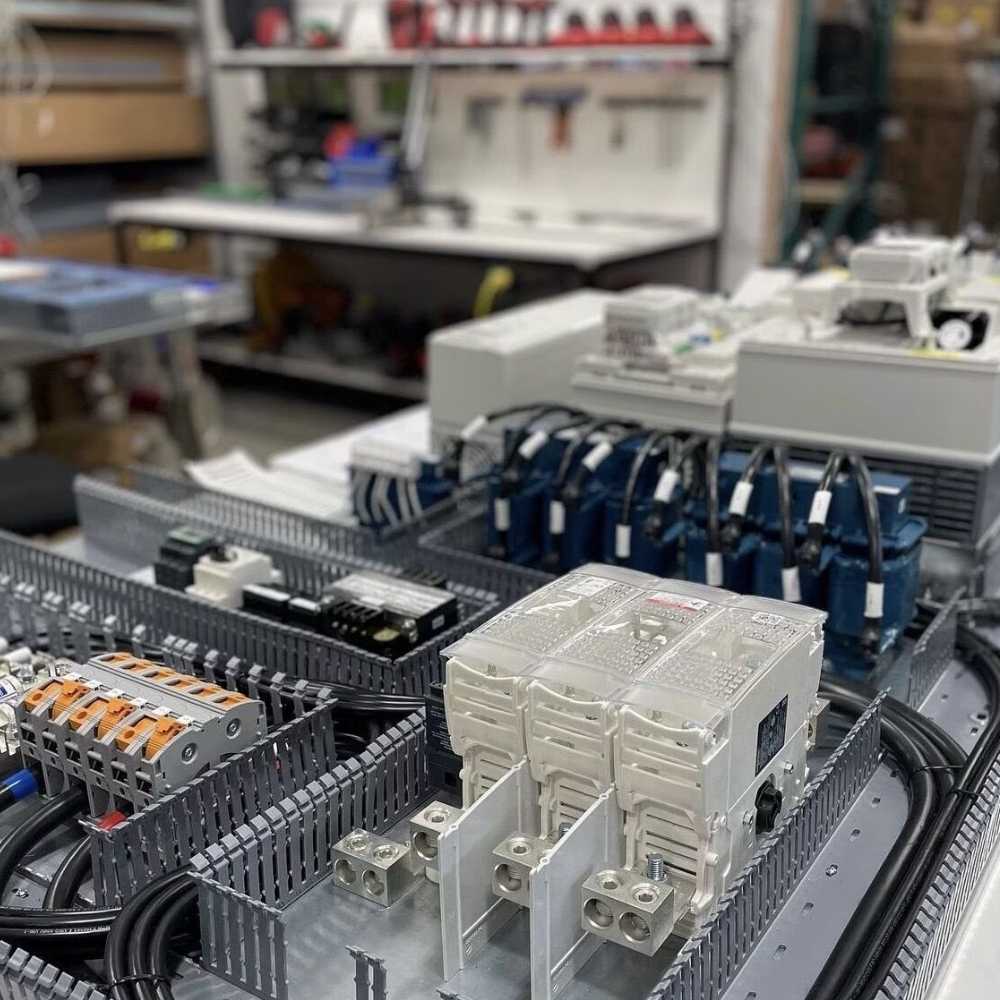

Programmable Logic Controllers (PLCs) are the cornerstone of modern industrial automation, enabling efficient control and automation of machinery and processes. In this article, we’ll explore how Omron PLCs work, their principles, and their applications in industrial environments. Whether you’re a seasoned professional or new to PLC technology, this comprehensive guide will enhance your understanding and appreciation of these vital devices.

What Is a Programmable Logic Controller (PLC)?

A Programmable Logic Controller (PLC) is an industrial computer designed to monitor inputs, make decisions based on its program, and control outputs to automate a process or machine. PLCs are essential in automation and control systems across various industries.

Key Components of a PLC

- Input Modules: These receive signals from sensors and other input devices.

- Central Processing Unit (CPU): Executes control instructions from the user-created program.

- Output Modules: Send control signals to actuators and other output devices.

- Power Supply: Provides the necessary power for the PLC and its modules.

- Programming Interface: Allows users to program the PLC using various programming languages like ladder logic.

How PLCs Work

PLCs monitor inputs from devices like switches, sensors, and input signals. Based on the logic in the program, the PLC executes control instructions and sends control signals to outputs like motors and valves, thereby controlling the actuators in the system.

How Do Omron PLCs Work in Industrial Automation?

Omron PLCs are renowned for their reliability and performance in industrial automation. They are designed to control and monitor complex industrial processes efficiently.

Working Principle of Omron PLCs

- Input Signal Acquisition: Omron PLCs receive signals from various sensors and actuators through input modules.

- Processing: The CPU processes these inputs based on the programming logic created by the user, often using languages such as ladder logic.

- Output Execution: The PLC sends instructions to output modules, which then control devices like motors and conveyor belts.

Features of Omron PLCs

- High-Performance: Capable of handling complex control tasks and process control.

- Scalability: Suitable for a wide range of applications, from small machines to large industrial processes.

- Robust Design: Built to withstand harsh industrial environments.

- Advanced Programming: Support for various programming languages and control algorithms.

For more information on specific Omron PLC models, you can visit our OMRON PLC page.

Applications of Omron PLCs in Industrial Automation

Omron PLCs are integral to numerous industrial settings, automating and controlling a variety of processes.

Common Applications

- Manufacturing Lines: Automation of production lines, including assembly and packaging.

- Motor Control: Precise motion control for motors in applications like general-purpose motor control applications.

- Conveyor Systems: Managing conveyor belts for material handling.

- Process Control: Monitoring and controlling production processes such as temperature, pressure, and flow.

- Safety Functions: Implementing safety functions to protect equipment and personnel.

By integrating Omron PLCs, industries achieve safe and efficient operations, enhancing productivity and ensuring compliance with safety standards.Looking to integrate Omron PLCs into your systems? Check out our Omron Industrial Automation solutions.

Understanding Safety PLCs: Ensuring Safe Automation and Control

In environments where safety is paramount, Safety PLCs play a crucial role in maintaining operational integrity.

What Are Safety PLCs?

Safety PLCs are specialized PLCs designed to execute safety-related control functions. Unlike standard PLCs, safety PLCs are built with redundancy and self-checking features to prevent failures that could lead to unsafe conditions.

Importance of Safety PLCs

- Compliance with Safety Regulations: Ensure systems meet industry safety standards.

- Protection of Personnel and Equipment: Monitor and control safety-critical functions.

- Integration with Automation Systems: Seamlessly work with existing automation systems for comprehensive control.

How Safety PLCs Work

Safety PLCs monitor inputs from safety devices like emergency stops and safety light curtains. They process this information and control outputs to bring systems to a safe state when necessary.

PLC Programming and Solutions Offered by Omron

Programming is a vital aspect of utilizing PLCs effectively. Omron offers comprehensive PLC programming tools and solutions to meet diverse industrial needs.

PLC Programming Languages

- Ladder Logic: The most commonly used language, resembling electrical relay logic.

- Function Block Diagram (FBD)

- Structured Text (ST)

- Sequential Function Charts (SFC)

Omron PLCs support various programming languages, allowing flexibility and ease of use.

Omron PLC Solutions

- Programming Software: User-friendly interfaces for writing and testing PLC programs.

- Hardware and Software Integration: Seamless communication between PLCs and other devices.

- Customization: Solutions tailored to specific control tasks and applications.

Whether you’re upgrading existing systems or implementing new ones, our Omron PLC Solutions can help you achieve your goals.

FAQs

What makes Omron PLCs suitable for industrial automation?

Omron PLCs are designed for robustness and flexibility, offering high-performance processing, compatibility with various sensors and actuators, and support for multiple programming languages. They are built to withstand harsh industrial environments and handle complex control tasks effectively.

How do Safety PLCs differ from standard PLCs?

Safety PLCs are specifically engineered to perform safety-critical functions with redundant systems and self-monitoring capabilities. They ensure compliance with safety regulations and protect both personnel and equipment by executing safety functions reliably.

Can Omron PLCs be integrated with existing automation systems?

Yes, Omron PLCs are highly compatible and can be integrated with various automation systems. They support standard communication protocols and offer customizable solutions to fit different industrial processes.

What programming languages are supported by Omron PLCs?

Omron PLCs support several programming languages, including ladder logic, Function Block Diagram (FBD), Structured Text (ST), and more. This flexibility allows programmers to choose the language that best fits their expertise and application needs.

Where can I find support and resources for Omron PLCs?

You can find a wealth of resources, including product information and support, on our website:

Omron PLCs

Omron HMI

Omron Servos

Omron Sensors

Conclusion

Omron PLCs are essential components in the realm of industrial automation, offering robust and flexible solutions for controlling and monitoring industrial processes. Understanding their working principles and applications empowers industries to optimize operations, enhance safety, and embrace the future of automation.

Looking to equip your operations with brand new and original Omron industrial accessories like PLCs, HMIs, Servos, Sensors, Relays, and more? We offer competitive prices and exceptional service. Contact us for a quotation today!