Discover how Omron’s programmable logic controllers have evolved over time and what future trends hold for industrial automation. This comprehensive guide is essential for anyone looking to enhance productivity and stay ahead in the field of automation.

A Brief History of Omron’s Programmable Logic Controllers (PLCs)

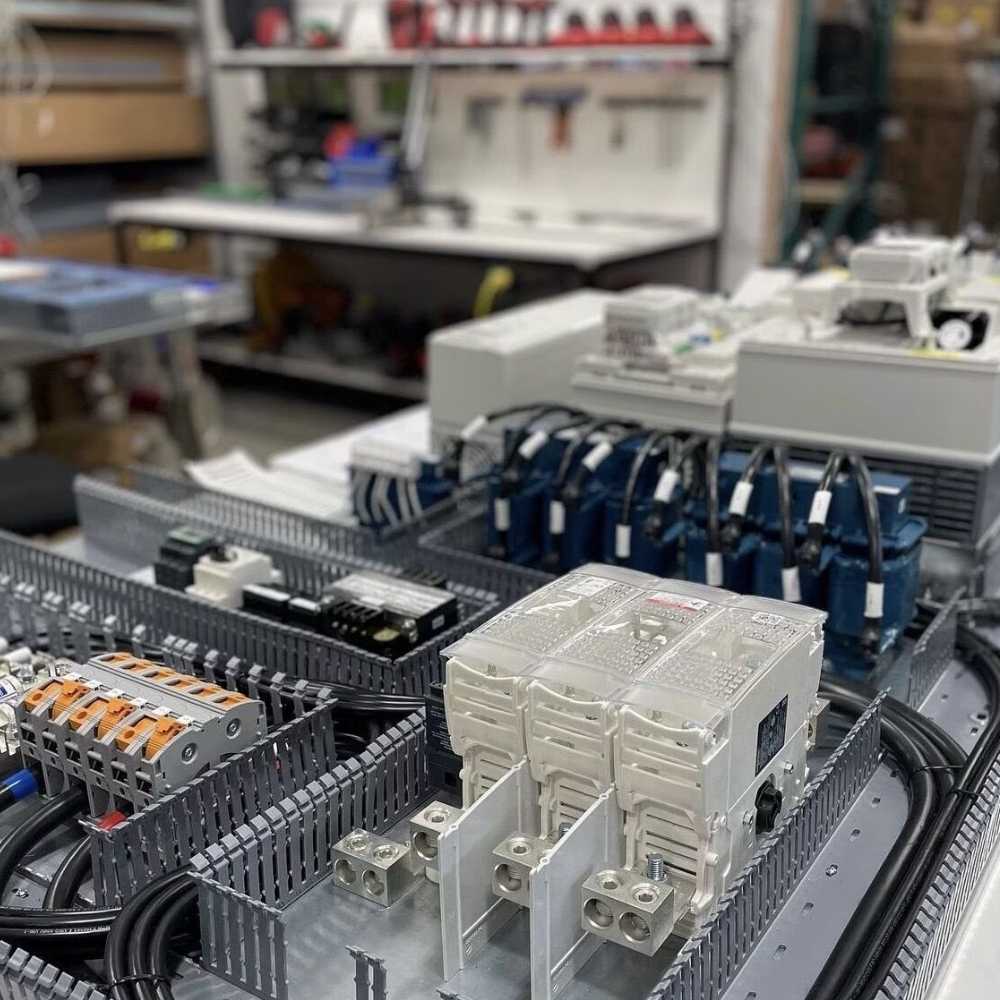

Omron Corporation, a global leader in industrial automation, has been at the forefront of innovation since its inception. The journey began in the late 1960s, a pivotal era for programmable logic controllers (PLCs). Omron introduced some of the first PLCs, revolutionizing the way industries approached machine control and automation tasks.PLCs were developed to replace complex relay-based control systems. Omron’s early PLCs offered real-time control and connectivity, enabling factories to achieve higher productivity and efficiency. Over the years, these controllers have become more sophisticated, featuring advanced processing capabilities and built-in functions tailored for specific industrial applications.Today, Omron’s PLCs are essential components in industrial control systems, facilitating the seamless integration of various devices and systems on the factory floor.

How Do Omron PLCs Revolutionize Industrial Automation?

Omron PLCs play a crucial role in the field of industrial automation. They act as the brains behind automation systems, controlling machinery and processes with precision. Here’s how they make a difference:

- Enhanced Control Systems: Omron’s PLCs offer advanced control of machinery and equipment, ensuring operations run smoothly under various environmental conditions.

- Seamless Connectivity: With the rise of the Industrial Internet of Things (IIoT), Omron PLCs provide connectivity solutions that enable factories to communicate real-time data across networks.

- Flexibility and Scalability: Omron’s modular PLCs, like the CJ2M-CPU34, allow for customization to meet specific application needs, making them suitable for both small-scale and large-scale operations.

Omron also focuses on integrating sensing and control technologies, which are essential for advanced automation and intelligent automation solutions.

The Evolution of PLC Technology: From the Late 1960s to Today

PLCs have come a long way since their inception. Initially designed to replace hard-wired relays, they have evolved to become sophisticated automation controllers with capabilities such as:

- Real-Time Processing: Modern PLCs handle real-time data processing, essential for time-critical operations.

- Enhanced Connectivity: Integration with industrial networks and the Internet of Things allows for better data exchange and monitoring.

- Improved Programming Languages: Support for programming languages like ladder logic and structured text makes PLC programming more accessible and versatile.

Omron has been instrumental in this evolution, consistently releasing innovative products like the CP1L-M40DT1-D, which offers advanced features not previously available in the market.

Future Trends in PLC Technology: What to Expect?

The future of PLCs is geared towards greater integration and smarter operations:

- Integration with Industrial PCs: Combining PLCs with industrial PCs for enhanced functionality.

- Edge Computing: Processing amounts of data closer to the source to reduce latency.

- Artificial Intelligence: Incorporating AI for predictive maintenance and smarter decision-making.

- Enhanced Security: Protecting industrial control systems from cyber threats.

Omron’s commitment to innovation suggests that they will continue to lead in these areas, providing automation solutions that meet the demands of the factory of the future.

Selecting the Right PLC for Your Automation Needs

Choosing the right PLC is crucial for optimizing industrial processes. Consider the following when selecting a PLC:

- Application Requirements: Assess the specific functions you need, such as motion control or sensor integration.

- Environment: Ensure the PLC can withstand your industrial environments and environmental conditions.

- Connectivity Needs: Look for PLCs with the necessary connectivity options for your network.

- Scalability: Opt for modular PLCs like the CJ1W-ID262 that allow for future expansion.

For personalized assistance, consider reaching out to Omron industrial distributors who can guide you based on your specific industrial needs.

FAQs

What makes Omron PLCs stand out in industrial automation?

Omron PLCs are renowned for their reliability, advanced features, and integration capabilities, making them ideal for various automation systems.

How do Omron PLCs integrate with the Industrial Internet of Things (IIoT)?

They offer enhanced connectivity options, allowing seamless data exchange and real-time monitoring within IIoT frameworks.

Can Omron PLCs handle advanced programming languages?

Yes, they support programming languages like ladder logic and structured text, enabling complex automation tasks.

How do I choose the right Omron PLC for my application?

Consider your specific application needs, and consult with experts or refer to resources like Omron Programmable Controllers for guidance.

Conclusion

Omron’s PLCs have significantly shaped the landscape of industrial automation. From their inception in the late 1960s to today’s advanced systems, they have become an essential component in optimizing industrial operations. As we look to the future, Omron continues to innovate, paving the way for smarter and more efficient factories.