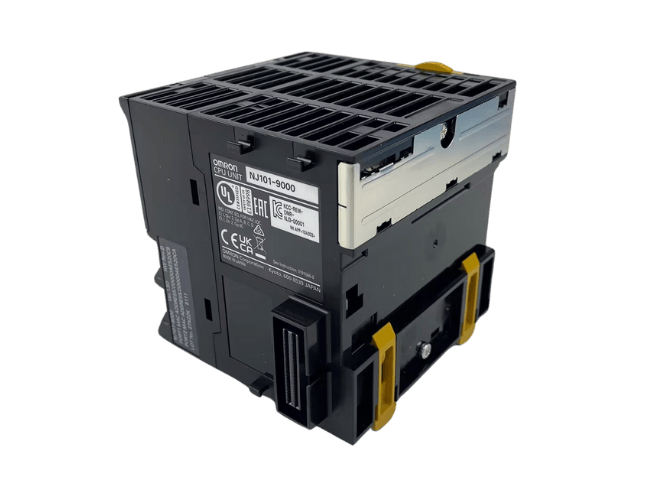

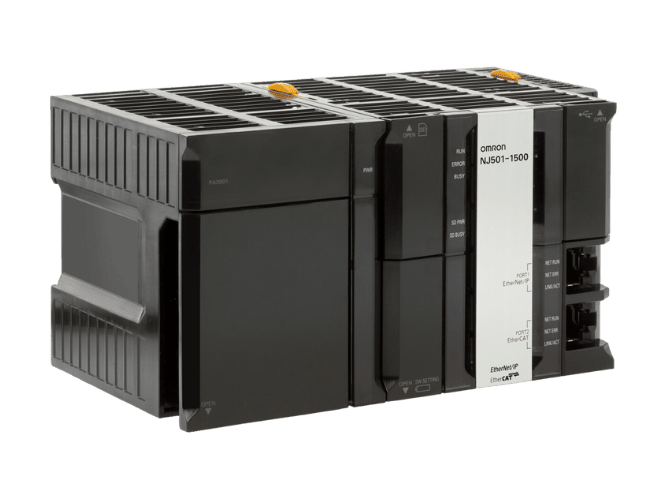

Omron NJ Series

The NJ Series stands at the forefront of Omron's commitment to improving manufacturing processes and contributing to a better society. This machine automation controller integrates multiple control functions into a single powerful unit, offering: Seamless Integration: Combines PLC and motion control functionality, Enhanced Productivity: Supports high-speed processing and precise motion control, Scalable Solutions: Adaptable for both small-scale equipment and complete production lines.

How Does the NJ Series Transform Manufacturing Operations?

In today’s rapidly evolving manufacturing landscape, the NJ Series addresses key challenges:

Advanced Control Capabilities

-

Supports up to 64 motion axes

-

Integrated safety functions

-

High-speed processing for complex operations

2.Connectivity and Communication

-

Built-in EtherNet/IP support

-

Seamless integration with HMI systems

-

Advanced database connectivity

What Are the Key Features of NJ Series CPU Units?

The NJ Series CPU units offer impressive specifications:

-

Motion Control: Up to 64 axes

-

Processing Speed: High-speed

-

Network Support: EtherNet/IP

-

Programming: Sysmac Studio

How Does the NJ Series Enable Industry 4.0 Implementation?

The NJ Series is designed to meet the demands of Industry 4.0:

Advanced Automation: Enables automation beyond human abilities.

Machine-Human Collaboration: Facilitates efficient interaction between operators and equipment.

Sustainable Production: Supports environmentally conscious manufacturing processes.

Frequently Asked Question

Find answers to common questions about Omron NJ Series and their functionalities.

The NJ Series is versatile and can handle applications ranging from small-scale equipment to entire production lines. It’s suitable for industries requiring high-speed processing, precise motion control, and integrated automation functions.

The NJ Series incorporates integrated safety features, allowing for safety control without the need for separate safety controllers. This integration simplifies system architecture and ensures compliance with safety standards.

The NJ Series supports various communication protocols, including built-in EtherNet/IP and EtherCAT connectivity. This enables seamless communication with a wide range of devices and systems.

Yes, the NJ Series is designed to meet Industry 4.0 demands by providing advanced automation capabilities, machine-human collaboration, and support for sustainable production processes.

Programming and configuration are performed using Sysmac Studio, an integrated software platform that offers a unified development environment for motion, logic, safety, and vision systems.

Yes, certain models of the NJ Series offer options for direct database connectivity, allowing for real-time data exchange between the controller and databases.

The NJ Series includes multiple models, such as the NJ1, NJ3, and NJ5, catering to different application sizes and complexity levels. For example, the NJ1 is suited for small applications with up to 2 axes of motion, while higher-end models can control up to 256 axes.

By integrating motion, logic, safety, vision, and HMI in one controller, the NJ Series simplifies system architecture and reduces setup times, leading to enhanced automation efficiency.

Combining PLC and motion control in a single unit eliminates the need for additional modules and reduces system complexity. This integration results in faster processing speeds and simplified programming.

The NJ Series features built-in EtherNet/IP and EtherCAT ports, facilitating high-speed and real-time communication with other devices and systems. This ensures timely data exchange and synchronization across the automation network.