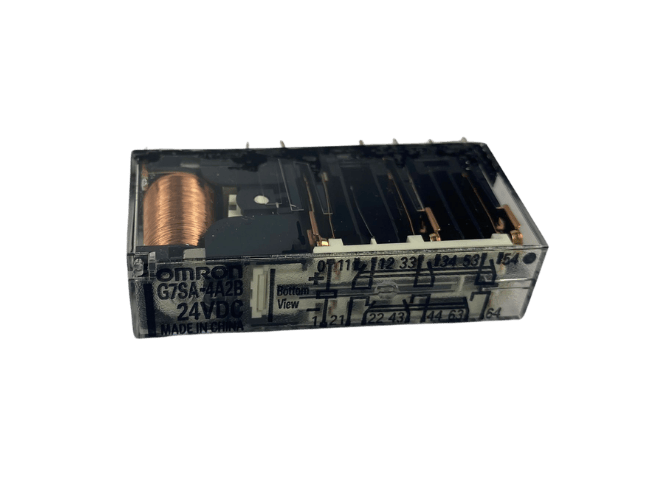

Omron Relays

Omron Industrial Automation has established itself as a trusted partner in manufacturing innovation through its extensive experience in sensing and control technology. Their relay solutions enable manufacturers to achieve greater productivity and streamlined efficiency in their operations.

What Makes Omron's Relay Product Categories Stand Out?

General Purpose Relays: Versatile switching capabilities, High reliability in various environments, Wide range of contact configurations, Compact design for space-saving installations.

Power Relays: High current handling capacity, Robust construction for demanding applications, Enhanced safety features, Ideal for motor control and heating applications.

Solid-State Relays (SSRs): High-speed switching capabilities, No mechanical wear, Silent operation, Long operational life.

How Do Omron Relays Enhance Industrial Control Systems?

Omron’s relay solutions contribute significantly to industrial automation by providing:

Enhanced Safety Features

-

High dielectric strength

-

Reliable contact separation

-

Built-in protection mechanisms

Versatile Applications

-

Motor control systems

-

Heating equipment

-

Signal processing

-

Safety circuits

Key Considerations for Implementation

Installation Requirements

-

Proper mounting orientation

-

Adequate ventilation

-

Protection from dust and moisture

Maintenance Guidelines

-

Regular visual inspections

-

Contact resistance testing

-

Environmental condition monitoring

Frequently Asked Question

Find answers to common questions about Omron Relays and their functionalities.

Mechanical lifespan: 10+ million operations.

Electrical lifespan: 100,000 to 500,000 operations depending on load conditions.

Actual lifetime varies based on operating environment and application.

Mechanical relays: Better for high-current applications, lower cost, visible switching.

Solid-state relays: Ideal for high-frequency switching, no mechanical wear, silent operation.

Consider factors like switching frequency, load type, and environmental conditions.

- Superior quality control and testing procedures.

- Comprehensive product range for various applications.

- Extended operational life.

- Global technical support network.

- Industry-leading innovation and reliability.

Most models operate reliably between -40°C to +85°C, special high-temperature variants available for extreme conditions, proper ventilation and heat dissipation required, regular monitoring recommended for optimal performance.

Regular visual inspection for damage or wear, periodic contact resistance measurements, environmental condition monitoring, cleaning of relay surroundings, documentation of operational history.

Check power supply and control signals, inspect for physical damage or contamination, measure contact resistance, verify proper connection and wiring, monitor operating temperature.

Yes, many models specifically designed for DC applications, available in various voltage ranges, special considerations for DC switching, built-in arc suppression in some models.

Calculate required switching current and voltage, consider environmental conditions, determine switching frequency needs, factor in space constraints, review safety requirements, assess load type and characteristics.

DIN rail mounting, PCB mounting, Socket mounting, Panel mounting, Custom mounting solutions available, Consider accessibility for maintenance.

Yes, Omron offers specially sealed and certified relays for hazardous locations, meeting international safety standards.