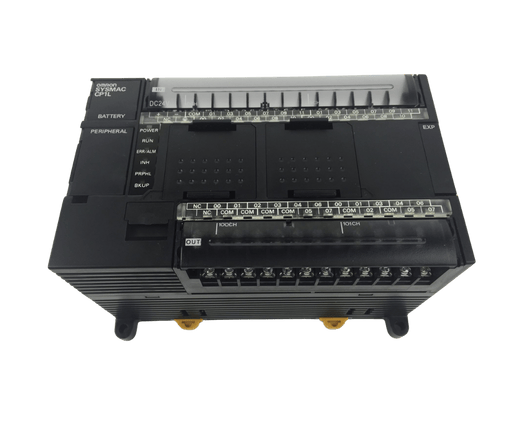

Omron PLC

Omron PLCs serve as the backbone of industrial automation by providing reliable control and automation solutions for various manufacturing processes. The Omron controller family includes several series like CS1, CJ2, and NX1, each designed to meet specific industrial needs. These programmable controllers excel in: Real-time process control Machine automation Complex control tasks Integration with other automation components

What Makes Omron PLC Series Stand Out?

The Omron PLC lineup offers remarkable scalability and functionality across different models:

CS1 Series: Ideal for large-scale automation systems, Supports advanced motion control, Enhanced communication protocols

CJ2 Series: Compact yet powerful design, Excellent Ethernet connectivity, Advanced input and output capabilities

CP Series: Perfect for smaller applications, Built-in IoT capabilities, Simplified interface options

How to Choose the Right Omron PLC for Your Needs?

Consider these key factors when selecting an Omron PLC:

-

System Size

-

Processing Speed

-

Communication

-

Scalability

-

Number of I/O points needed

-

CPU requirements

-

Required protocols

-

Future expansion needs

Integration and Communication Capabilities

Omron PLCs excel in connectivity through:

-

Industrial Ethernet

-

DeviceNet

-

Serial communication

-

Integration with HMIs and vision systems

The CX-One software platform provides a unified environment for:

-

Programming

-

Configuration

-

Monitoring

-

Troubleshooting

Frequently Asked Question

Find answers to common questions about Omron PLC and their functionalities.

Omron PLCs stand out for their reliability, comprehensive software tools, and extensive compatibility with various automation components.

With proper maintenance, Omron PLCs can run continuously for extended periods, often lasting 10-15 years or more.

Yes, Omron PLCs offer excellent integration with other devices through multiple communication protocols and interfaces.

Omron PLCs support multiple programming languages including Ladder Logic, Structured Text, and Function Block Diagrams.

Implement regular maintenance schedules and utilize built-in predictive maintenance features to minimize downtime.

Omron provides comprehensive technical support including specialized software tools, documentation, training programs, and direct access to automation experts.

Omron PLCs offer excellent scalability through expansion racks, additional I/O modules, and seamless integration with other automation components.

Yes, Omron PLCs excel in motion control applications, supporting multiple axes of motion, real-time positioning, and advanced actuator control through their Sysmac platform.

Omron PLCs include built-in safety features such as supervisory functions, redundancy options (especially in the CS1D series), and comprehensive error detection capabilities.

Omron PLCs fully support Industry 4.0 through IoT connectivity, industrial ethernet protocols, remote monitoring capabilities, and advanced data analytics features.