Are you intrigued by how Omron PLCs are transforming the world of automation? This article delves into the heart of programmable logic controllers, exploring their core components and functions. Whether you’re new to PLCs or looking to deepen your understanding, this guide is essential reading for anyone involved in industrial automation.

What Is a PLC and How Does It Impact Industrial Automation?

A Programmable Logic Controller (PLC) is a specialized computer used to control machinery and processes in industrial settings. PLCs are integral to automation systems, enabling precise control over industrial processes without the need for manual intervention.Omron PLCs, in particular, stand out due to their robustness and versatility. They are designed to handle complex control tasks, from motion control to data processing, making them ideal for a wide range of automation applications.

Key Impacts of PLCs in Automation:

- Efficiency: PLCs reduce downtime by quickly processing inputs and executing outputs.

- Flexibility: Easily reprogrammed to adapt to different tasks.

- Scalability: Systems can be expanded with additional modules and racks.

Omron offers a comprehensive range of PLCs, such as the CJ2M-CPU34, to meet various automation needs.

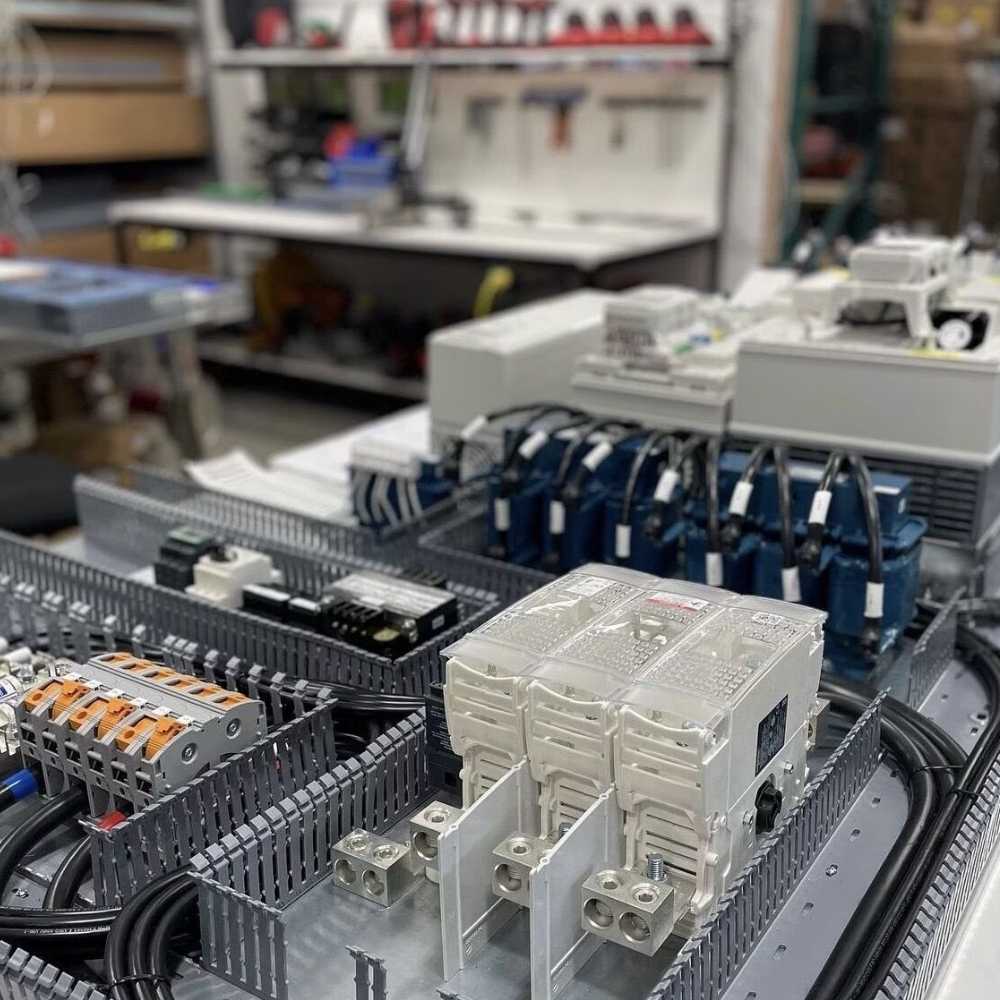

Exploring the Core Components of a PLC System

Understanding the components of a PLC is crucial for leveraging its capabilities. A typical PLC system comprises:

- Central Processing Unit (CPU): The brain of the PLC, processing input signals and executing the programme. Omron’s CPUs are known for their high-speed processing and reliability.

- Input/Output (I/O) Modules: Interface between the PLC and the external environment. They handle both analog and digital inputs and outputs, connecting to sensors, switches, and actuators.

- Power Supply: Supplies necessary power to the PLC and its components. The CJ1W-PA202 ensures stable power for consistent operations.

- Communication Interface: Allows the PLC to communicate with other devices and networks, such as Ethernet, for real-time data exchange.

- Programming Device and Software: Tools used to create and upload the programme to the PLC. Omron’s programmable controllers support languages like structured text and ladder logic.

Components Overview Table:

| Component | Function |

|---|---|

| CPU | Processes instructions and controls operations |

| Input Modules | Receive signals from input devices |

| Output Modules | Send signals to output devices |

| Power Supply | Provides power to the PLC system |

| Communication Interface | Enables data exchange with other systems |

| Programming Software | Allows users to create and modify programs |

How Do Omron PLCs Control Industrial Processes Effectively?

Omron PLCs control industrial processes by continuously monitoring inputs and making decisions based on the programme logic. This real-time control allows for:

- Precision: Accurate control of processes like temperature, pressure, and flow.

- Consistency: Uniform production quality by minimizing human error.

- Adaptability: Quick adjustments to changing production demands.

For instance, in a manufacturing line with conveyor belts and robotic arms, an Omron PLC like the CP1L-M40DT1-D can synchronize operations to enhance efficiency.

Features Enhancing Control:

- High-Speed Counters and Pulse Outputs: For precise motion control and positioning.

- Analog and Digital I/Os: Flexibility in handling various signal types.

- Multi-Axis Positioning Control: Managing complex movements in machinery.

PLCs control output devices based on input signals from sensors, executing commands in a fraction of a second. This swift response is essential for maintaining optimal production rates and ensuring safety in industrial operations.

Why Is Scalability Important in PLC Systems?

Scalability is a critical factor when designing automation systems. A scalable PLC system allows for:

- Expansion: Adding more I/O modules or communication modules as needed.

- Customization: Tailoring the system to specific automation tasks.

- Cost-Effectiveness: Investing in only what is necessary, with room to grow.

Omron PLCs like the CS1D series offer modular designs with expansion racks, providing the flexibility to adapt to evolving requirements.

Benefits of Scalability:

- Future-Proofing: Accommodate new technologies and processes.

- Ease of Integration: Simplify adding new machinery or production lines.

- Resource Optimization: Efficient use of hardware and software resources.

By choosing scalable solutions, businesses can ensure their automation infrastructure remains relevant and efficient over time.

Choosing the Right Omron Programmable Controllers for Your Automation Needs

Selecting the right Omron PLC involves considering factors such as:

- Application Complexity: For simple tasks, compact PLCs like the CP1E series may suffice. For complex operations, the CJ2 series offers advanced features.

- I/O Requirements: Assess the number of inputs and outputs needed.

- Communication Needs: Determine if Ethernet, serial, or other interfaces are required.

- Environmental Conditions: Consider temperature, humidity, and vibration.

Tips for Selection:

- Define Your PLC Needs: Clearly outline what you need the PLC to accomplish.

- Consult Experts: Reach out to Omron industrial distributors for guidance.

- Consider Compatibility: Ensure the PLC is compatible with existing equipment and programming software.

By carefully evaluating these factors, you can choose a PLC that not only meets current demands but is also adaptable for future needs.

FAQs

What are the main components of a PLC?

The main components of a PLC include the CPU, input/output modules, power supply, communication interface, and programming device.

How do PLCs improve industrial automation?

PLCs enhance industrial automation by providing precise control over processes, reducing manual intervention, and increasing efficiency and safety in industrial settings.

Why choose Omron PLCs over others?

Omron PLCs are known for their reliability, scalability, and advanced features like high-speed counters and multi-axis positioning control, making them suitable for a wide range of applications.

Can Omron PLCs handle both analog and digital signals?

Yes, Omron PLCs support both analog and digital signals, allowing for versatile integration with various input/output devices.

What programming languages are supported by Omron PLCs?

Omron’s programmable controllers support programming languages like structured text and ladder logic, providing flexibility for different programming preferences.

How do I ensure compatibility with existing automation systems?

Check the interface and communication modules of the PLC to ensure they are compatible with your existing systems. Consulting with Omron industrial distributors can provide valuable insights.

Conclusion

Understanding the core components and functions of Omron PLCs is essential for anyone involved in industrial automation. These powerful tools offer the versatility, scalability, and reliability needed to optimize industrial processes and drive efficiency.

Ready to upgrade your automation systems? Our company provides brand new and original Omron industrial accessories, including PLCs, HMIs, Servos, Sensors, and Relays. The price is competitive—contact us today for a quotation!