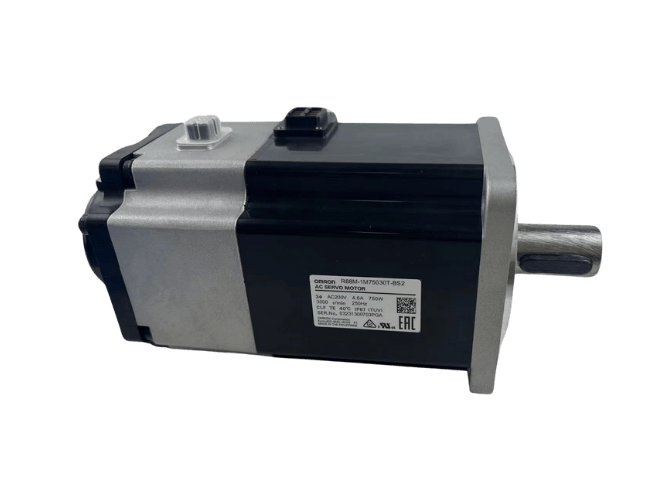

Omron Servos

Omron servo motors are advanced motion control devices that form a crucial part of industrial automation solutions. These precision instruments combine sophisticated control technology with reliable performance to deliver: High-precision positioning, Consistent speed control, Enhanced torque management, Improved machine efficiency.

How Do Omron Servo Systems Enhance Manufacturing Operations?

Performance Benefits

- Speed and Accuracy: Omron servo systems provide exceptional positioning accuracy

- Energy Efficiency: Advanced power management features reduce operational costs

- Reliability: Built to industrial standards for long-term performance

- Integration Capabilities: Seamless compatibility with EtherCAT communications

What Makes Omron Servo Motors Stand Out?

The distinguishing features of Omron servo motors include:

-

Built-in safety functions

-

Advanced motion control

-

Integrated feedback systems

-

Multiple mounting options

-

Scalable solutions

How to Select the Right Omron Servo System?

Consider these factors when choosing an Omron servo system:

Application Requirements

-

Load characteristics

-

Speed requirements

-

Precision needs

-

Environmental conditions

System Integration

-

Communication protocols

-

Control architecture

-

Software compatibility

Frequently Asked Question

Find answers to common questions about Omron Servos and their functionalities.

Regular maintenance checks and proper installation are essential for optimal performance.

Omron servo drives include multiple safety functions such as emergency stop and position monitoring.

Yes, Omron servo motors are designed for seamless integration with various automation platforms.

Start with basic diagnostics using the Sysmac Studio software and consult the manual for error codes.

Omron servo motors offer precise motion control, high energy efficiency, reliable performance, and seamless integration with EtherCAT communications, making them ideal for advanced industrial automation applications.

Consider factors like required torque, speed range, precision requirements, environmental conditions, and compatibility with your existing automation system. Consult Omron’s sizing tools for accurate selection.

Regular maintenance includes checking electrical connections, monitoring bearing conditions, ensuring proper cooling, inspecting feedback devices, and updating firmware when necessary. Follow the maintenance schedule in the manual.

While Omron servo drives are optimized for use with Omron motors, some models can work with third-party motors. However, this may require additional configuration and could limit some advanced features.

Start by checking the error code in Sysmac Studio, verify proper wiring connections, ensure proper parameter settings, and consult the troubleshooting guide in the user manual for specific error resolution steps.

Omron servo systems include built-in safety features such as Safe Torque Off (STO), position monitoring, speed monitoring, and emergency stop functions, all compliant with international safety standards.